ULTRASONIC SPRAY ELECTRONICS

Ultrasonic spray has the advantages of precise and controllable spray flow rate, thin and uniform coating, and controllable spray range. It is very suitable for spraying electronic products and is increasingly used for research and production. Ultrasonic spray technology can be used to deposit a uniform coating on substrates of any width. Ultrasonic Spray Electronics technology enables these very thin coatings to be produced with extremely high uniformity, resulting in very accurate and repeatable results to enhance product functionality.

TOUCH SCREEN

Ultrasonic spray has significant advantages over other coating methods for functional glass coatings such as Transparent Conductive Oxide coatings.

- Utilization rate of solution reaches 95% and above.

- Very thin, uniform, durable layers

- Drastically reduced maintenance compared to pressure spray

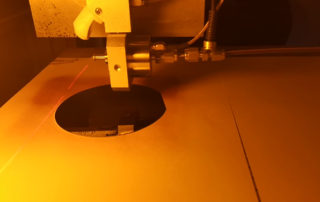

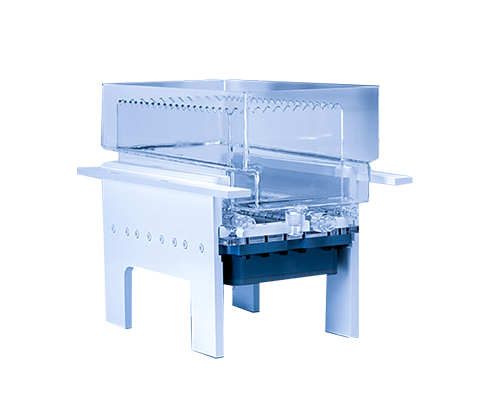

MEGASONIC CLEANING SYSTEMS

Cheersonic can provide megasonic cleaning equipment with a frequency of 900kHz-3000kHZ. Ultra-high frequency ultrasonic waves at the megahertz level have higher cleaning accuracy and are widely used in semiconductor cleaning, development, glue removal, etching and other fields.

Very low ultrasonic cavitation effect, no damage to the device surface.

Ultra-high cleaning accuracy.

- High corrosion resistance, resistant to various acid and alkali solutions and organic solvents.

5G HEAT DISSIPATION MATERIAL

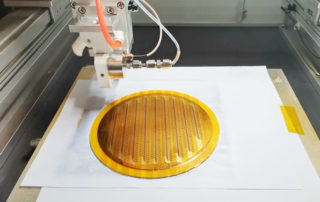

Ultrasonic heat-dissipating material slicer has fast cutting speed, smooth and flat incision, time-saving, high-efficiency and labor-saving.

The cut surface is smooth and beautiful.

Simple and fast product positioning, multi-functional and all-round cutting according to needs.

During the slitting process, the operation is automatically completed without human intervention, which improves work efficiency.

Recommended Popular Devices

Advantage:

- Ability to spray small target areas

- Uniform flux application

- Ability to control flux thickness, coating thickness is only about 20 microns

- Uniform film coverage of various surface contours

- Not blocked

- Reproducible spray process

- Ability to deposit highly uniform thin nanolayers

- Ultrasonic vibrations suspend solids in solution

- Get very accurate and repeatable results to increase product efficiency

- Reduce process waste and overspray

- Improve process efficiency and make OLEDs more economically viable

Application:

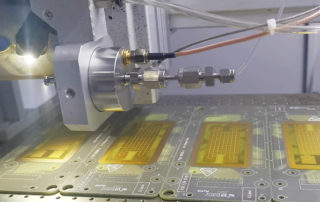

- Spray flux

- Photoresist

PCB flux

Flux brazing

Flip chip

Precision electronics

- Carbon nanotubes

- Graphene coating

- OLED

- Transparent conductive oxide

- Sensor manufacturing

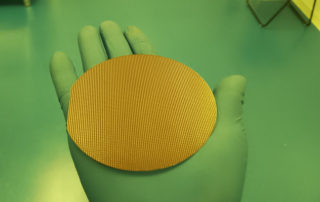

- Semiconductor

- Welding powder

To reach our anytime via email please fill out the form below with your request and a company representative will reply to you. To find your local CHEERSONIC representative to connect directly click your region in the contact drop down menu.

Contact CHEERSONIC For immediate assistance please contact us the corporate headquarters during business hours at 6:00 am – 22:00 pm.

Tel: 0571-87910406

- Mobile: +86 13588732518

- Email: Market2@cheersonic.com

Add: 11-13 Chuangye Road, Changkou, Fuyang, Hangzhou, Zhejiang, China