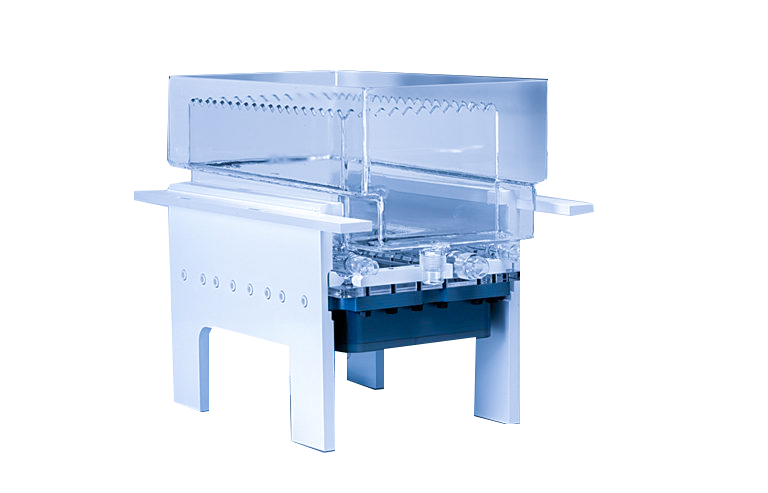

Batch Type Megasonic Plate

We specialize in providing customized solutions to meet the needs of emerging cutting-edge industries such as nanotechnology, fuel cells, semiconductors, medical coatings, spray pyrolysis and more.

The application in microelectronics production greatly reduces the amount of chemicals and ultrapure water, and reduces the residence time of the wafer in the chemical solution. Compared with the traditional cleaning method and the ultrasonic cleaning system, the damage to the substrate features is minimal. Using the liquid flow generated by the megahertz wave to realize the cleaning process has the ability to remove deep sub-micron particles, which can meet the requirements of the 0.1-micron line width technology for the cleaning process, and has been widely used in the cleaning process of silicon-based chips. So far, the megasonic cleaning method has become the most widely used and effective method in polishing wafer cleaning. Generally, the particle size suitable for removal by megasonic cleaning is 0.1~0.3 μm, and the particle size suitable for removal by ultrasonic cleaning is above 0.4 μm. The effect of megasonic cleaning is gentler. Therefore, an appropriate vibration frequency should be selected according to the size of the particles to be removed and the impact force that the device on the wafer surface can withstand.

- CMP chemical mechanical polishing

- Cleaning before bonding

- Mask cleaning

- Development

- Lift-off Metal Stripping

- Wet etching

- Lens cleaning

- Precision cleaning in the microelectronics industry such as display screens

- Silicon

- GaAs

- Indium Phosphide

- Gallium Nitride

- Silicon carbide

- Lithium Niobate

- Lithium tantalate, etc.

PERFECTING YOUR PROCESS

Features

• 1MHz UHF Ultrasonic

• The sound field is uniform, and the sound intensity can exceed 6W/cm2

• Stainless steel or quartz material vibration plate

• Unique transducer fitting technology, high stability and longer life

• Megasonic generator of second generation semiconductor technology

Basic Specifications

• Megasonic frequency 1MHz, 750kHz

• Maximum sound intensity 5.5W/cm2

• Maximum power 1200-4800W

• Housing material PVC

• Vibration plate material: 316L stainless steel, quartz

• Suitable for wafers 6″, 8″, 12″

• Liquid temperature <70°C

• Ambient temperature 10-40°C

OUR EXPERTISES

Cheersonic offers innovative and customized solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your production.

To reach our anytime via email please fill out the form below with your request and a company representative will reply to you. To find your local CHEERSONIC representative to connect directly click your region in the contact drop down menu.

Contact CHEERSONIC For immediate assistance please contact us the corporate headquarters during business hours at 6:00 am – 22:00 pm.

Tel: 0571-87910406

- Mobile: +86 13588732518

- Email: Market2@cheersonic.com

Add: 11-13 Chuangye Road, Changkou, Fuyang, Hangzhou, Zhejiang, China