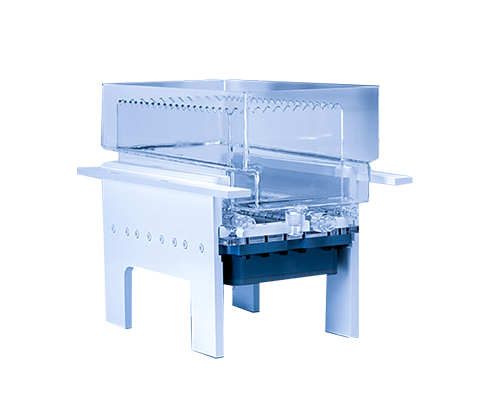

Megasonic Cleaning Systems

Megasonic energy is currently a very widely used cleaning method. After adding megasonic energy, the use temperature and process time of the solution can be greatly reduced, and the cleaning effect is more effective. The commonly used frequency of megasonic cleaning is 800kHz-1 MHz, and the megasonic power is 100-600W. Compared with ultrasonic cleaning, the effect of megasonic cleaning is milder. The appropriate vibration frequency should be selected according to the particle size to be removed and the impact force that the device on the wafer surface can withstand. Generally, the particle size suitable for removal by megasonic cleaning is 0.1~0.3 μm, and the particle size suitable for removal by ultrasonic cleaning is above 0.4 μm.

Megasonic Cleaning Technology

- CMP chemical mechanical polishing

- Cleaning before bonding

- Mask cleaning

- Development

- Lift-off Metal Stripping

- Wet etching

- Lens cleaning

- Precision cleaning in the microelectronics industry such as display screens

- Various frequencies to choose from

- Excellent cleaning effect

- A variety of megasonic cleaning methods are available

- Various tank structures and materials, suitable for various cleaning solutions

- Higher stability and durability

- The effect of megasonic cleaning is gentler and will not cause damage to the surface of the device

- Ultra-high cleaning accuracy, can remove 0.1~0.3 μm dirt particles on the surface of the object

- High corrosion resistance, resistant to various acid and alkali solutions and organic solvents

OUR EXPERTISES

Cheersonic offers innovative and customized solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your production.

To reach our anytime via email please fill out the form below with your request and a company representative will reply to you. To find your local CHEERSONIC representative to connect directly click your region in the contact drop down menu.

Contact CHEERSONIC For immediate assistance please contact us the corporate headquarters during business hours at 6:00 am – 22:00 pm.

Tel: 0571-87910406

- Mobile: +86 13588732518

- Email: Market2@cheersonic.com

Add: 11-13 Chuangye Road, Changkou, Fuyang, Hangzhou, Zhejiang, China