SEMICONDUCTOR COATING

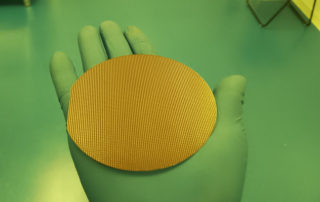

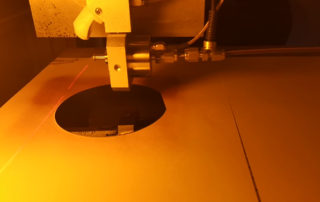

The ultrasonic coating system can use advanced layering technology to precisely control the flow rate, coating speed and deposition amount. Low-speed spray forming defines an atomizing spray as a precise, controllable pattern, avoiding excessive spraying when producing very thin and uniform layers. It turns out that direct spraying using ultrasonic technology is a reliable and effective way to deposit photoresist on 3D microstructures, thereby reducing equipment failures caused by excessive metal exposure to etchant.

Ultrasonic spray systems have proven to be suitable for a variety of applications that require uniform, repeatable photoresist or polyimide film coatings. Cheersonic’s coating system can control thicknesses from sub-micron to more than 100 microns, and can coat any shape or size. It is a feasible alternative to other coating technologies such as spin coating and traditional spray coating.

Cheersonic’s non-blocking ultrasonic coating technology is known for its ultra-thin micron-layer coatings of functional and protective materials. The ultrasonic vibration of the nozzle effectively dispersed the particles in the suspension and produced a very uniform particle dispersion in the film layer, while the conductive particles did not settle out of the suspension.

ULTRASONIC COATING TECHNOLOGIES FOR SEMICONDUCTOR

- Uniform thin film coverage of various surface profiles

- High uniformity and uniformity

- Non-contact spraying

- Micro-flow spraying, multiple liquid feeding schemes

- High speed control accuracy

- High liquid utilization

- Ability to deposit thin single micron layers with high uniformity

- Repeatable proven spray process

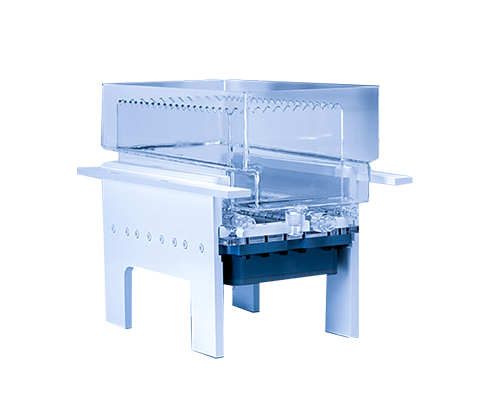

EQUIPMENT SOLUTIONS

OUR EXPERTISES

Cheersonic offers innovative and customized solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your production.

To reach our anytime via email please fill out the form below with your request and a company representative will reply to you. To find your local CHEERSONIC representative to connect directly click your region in the contact drop down menu.

Contact CHEERSONIC For immediate assistance please contact us the corporate headquarters during business hours at 6:00 am – 22:00 pm.

Tel: 0571-87910406

- Mobile: +86 13588732518

- Email: Market2@cheersonic.com

Add: 11-13 Chuangye Road, Changkou, Fuyang, Hangzhou, Zhejiang, China