Why has AEM attracted attention this year?

The hotness of the AEM market can be summarized as the background of the gradual increase in the proportion of wind/solar power under the premise of the promotion of the hydrogen energy market. In the context of insufficient confidence in PEM water electrolysis, it is possible to enter the AEM track with more technical prospects at a lower threshold.

It can be divided into four aspects:

- The driving force of the development of the green hydrogen market: Globally, the emphasis on renewable energy and reducing carbon emissions has been increasing. In this context, the production and application of green hydrogen as a clean energy carrier have gradually attracted widespread attention. Although the fuel cell market is not strong at present, market participants have gradually realized that the key to the large-scale commercialization of fuel cell technology lies in the large-scale production of green hydrogen. Therefore, the focus of the market has shifted from the application end in previous years to the hydrogen production end. This shift has provided opportunities for the development of anion exchange membrane water electrolysis (AEM) technology.

- The background of the gradual increase in the proportion of wind/solar power: Under the trend of increasing proportion of wind/solar power in the energy structure, green hydrogen preparation technology that can adapt to fluctuating energy is particularly important. The hydrogen production technologies currently on the market can be divided into three categories: low-temperature, medium-temperature and high-temperature water electrolysis technologies. However, medium-temperature and high-temperature electrolyzers are best suited to operate under constant load conditions and are not easy to start/stop frequently, which limits their application in dealing with fluctuating intermittent energy sources such as wind and solar energy.

- In this context, only low-temperature water electrolysis technology can meet the requirements. There are currently two low-temperature water electrolysis technologies on the market: AEM-WE and PEM-WE. PEMWE faces challenges in recent developments to improve hydrogen production efficiency and reduce costs, resulting in a decline in market confidence, which has also prompted the industry to shift its attention to another low-temperature water electrolysis technology – AEM-WE.

- Hope to seize the future market: There is currently a view in the market that with the breakthrough of AEM-WE technology, PEM-WE technology may become unnecessary and even be considered a transitional product. This view also allows many companies to skip the research and development of PEM-WE technology and directly deploy AEM-WE technology to seize the future market. However, this view may ignore the respective advantages and applicable scenarios of the two technologies. Directly deploying AEM technology may be a strategy to seize the future market, but it is also necessary to consider the maturity of the technology and the market’s acceptance.

- Commonality between AEM-WE, PEM-WE and PEMFC: AEM-WE has certain similarities with PEM-WE and PEMFC electrolyzers in structure. On the one hand, it reduces the threshold for switching from PEM-WE and PEMFC technology to AEM-WE technology, making it easier for companies that have already deployed PEM technology to transition to the AEM-WE track. On the other hand, with the rapid development of PEMFC and PEM-WE technologies in the early stage, core component manufacturers have also iterated and accumulated technology in this process, and can carry out customized development according to more specific requirements, providing the basic conditions of materials and technology for the large-scale development of AEM-WE.

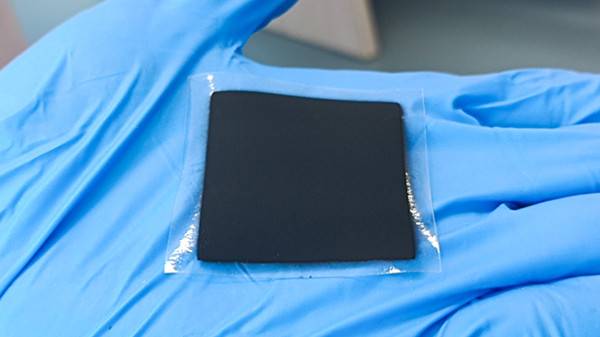

Hydrogen production by electrolysis of water is the most advantageous method for producing hydrogen. Utrasonic coating systems are ideal for spraying carbon-based catalyst inks onto electrolyte membranes used for hydrogen generation. This technology can improve the stability and conversion efficiency of the diaphragm in the electrolytic water hydrogen production device. Cheersonic has extensive expertise coating proton exchange membrane electrolyzers, creating uniform, effective coatings possible for electrolysis applications.

Cheersonic ultrasonic coating systems are used in a number of electrolysis coating applications. The high uniformity of catalyst layers and even dispersion of suspended particles results in very high efficiency electrolyzer coatings, either single or double sided.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions