Ultrasonic Spraying for Anti-reflective (AR) Coatings

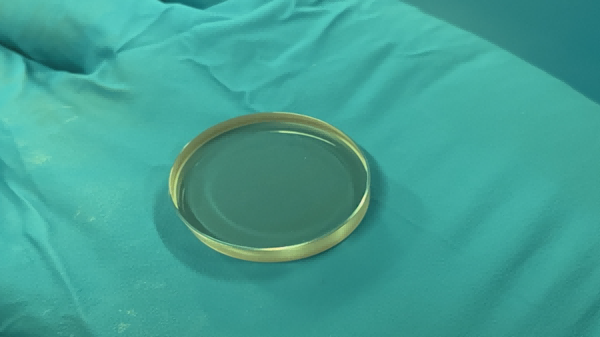

Ultrasonic spraying for anti-reflective (AR) coatings on glass surfaces is a widely utilized application that significantly enhances the performance and functionality of glass in various industries. This advanced technology employs ultrasonic atomization to create a fine mist of coating material, which is then precisely applied to the glass surface. The result is a uniform and consistent layer that effectively reduces surface reflections, thereby improving light transmission properties.

By minimizing reflections, AR coatings allow more light to pass through the glass, which is particularly beneficial in applications such as optical devices, solar panels, and display screens. In the realm of optics, for instance, AR coatings enhance the clarity and brightness of lenses, making them essential in eyeglasses, camera lenses, and microscopes. In the solar energy sector, these coatings increase the efficiency of solar panels by maximizing the amount of light absorbed, ultimately improving energy conversion rates.

Moreover, ultrasonic spraying offers several advantages over traditional coating methods. The precision of ultrasonic atomization ensures minimal overspray and waste, leading to more efficient use of materials. This technique also allows for better control over the thickness of the coating, which is crucial for achieving the desired optical properties without compromising the glass’s transparency or quality.

In addition to its applications in optics and energy, ultrasonic spraying of AR coatings is also essential in the automotive and architectural glass industries. It enhances the aesthetic appeal and functionality of windows and windshields by providing improved visibility and reducing glare.

Overall, the integration of ultrasonic spraying technology in the application of anti-reflective coatings is transforming the way we utilize glass across various fields, driving innovation and improving product performance. As industries continue to seek enhanced optical properties and energy efficiency, ultrasonic spraying will remain a critical component in the advancement of glass technologies.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions