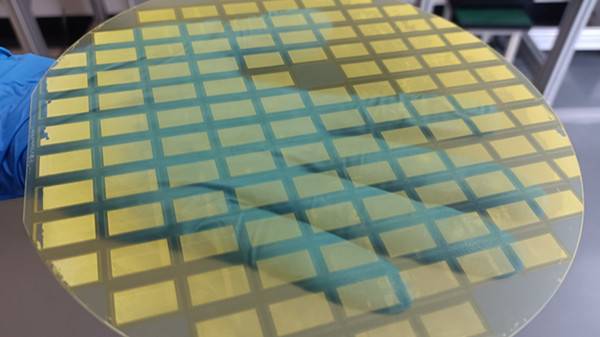

Ultrasonic Coating of Quantum Dot Solution on Wafer

Ultrasonic coating of quantum dot solution on wafer is an advanced coating technology, which combines the advantages of ultrasonic atomization and precision spraying, and can achieve uniform and efficient coating of quantum dot solution on the surface of wafer. The following is a detailed analysis of the technology:

Technical principle

The ultrasonic spray coating machine uses high-frequency ultrasonic vibration to atomize the quantum dot solution into tiny particles, which form a uniform suspension in the gas medium. Subsequently, the suspension is sprayed onto the surface of the wafer through a precisely controlled nozzle to form a uniform and dense quantum dot film.

Advantages

- High coating uniformity:

Ultrasonic spraying technology can ensure that the quantum dot solution forms a highly uniform coating on the surface of the wafer. This is particularly important for application scenarios that require precise control of coating thickness and distribution, such as semiconductor manufacturing, optoelectronic devices and other fields. - Precise coating thickness control:

The thickness of the coating can be precisely controlled by adjusting the frequency, amplitude and spraying parameters (such as spraying speed, nozzle distance, etc.) of the ultrasonic wave. This is of great significance for the preparation of quantum dot films with specific performance requirements. - Non-contact spraying:

Ultrasonic spraying is a non-contact spraying technology that can avoid mechanical damage and contamination to the wafer surface. This is essential to protect the cleanliness and integrity of the wafer surface. - Strong applicability:

Ultrasonic spraying technology is applicable to many types of quantum dot solutions and wafer substrates. Whether it is inorganic quantum dots or organic quantum dots, whether it is silicon wafers or other semiconductor materials, this technology can be used for coating. - High production efficiency:

Ultrasonic spraying machines have a faster spraying speed and a higher degree of automation, which can significantly improve production efficiency. This is of great significance for the large-scale production of competitive quantum dot film products.

Application

Ultrasonic spraying machines have a wide range of application scenarios for coating quantum dot solutions on wafers, including but not limited to:

- Semiconductor manufacturing: In the process of semiconductor device manufacturing, quantum dot films can be used to improve the performance and stability of devices. Through ultrasonic spraying technology, quantum dot films can be accurately coated on the surface of wafers to meet the needs of device manufacturing.

- Optoelectronic devices: Quantum dot films have important applications in optoelectronic devices such as LEDs and solar cells. Through ultrasonic spraying technology, quantum dot films can be coated on key parts of optoelectronic devices to improve the photoelectric conversion efficiency and stability of the device.

- Biomedicine: Quantum dots have broad application prospects in the biomedical field, such as bioimaging, drug delivery, etc. Through ultrasonic spraying technology, quantum dot films can be coated on devices such as biochips or medical sensors to achieve more efficient biological detection and diagnosis.

In summary, coating quantum dot solution on a wafer with an ultrasonic sprayer is an efficient, precise and adaptable coating technology with broad application prospects and important research value.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions