Ultrasonic Coating for Proton Exchange Membrane Fuel Cell

Ultrasonic Coating for Proton Exchange Membrane Fuel Cell – Cheersonic

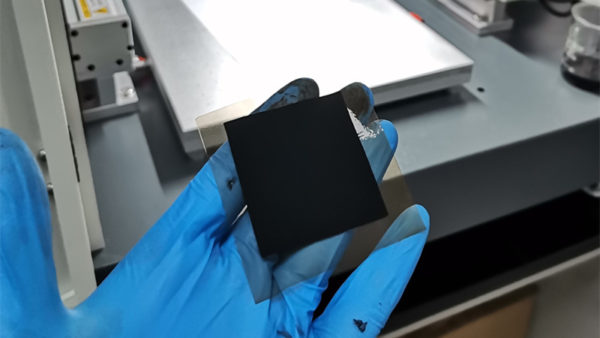

Proton exchange membrane fuel cells (PEMFCs) are a promising green energy source due to their advantages of high power, high efficiency, no harmful emissions, high-quality power, scalability, and fast start-up. Since the MEA is the most expensive component in a fuel cell, reducing the platinum loading of the MEA is an important area of research in fuel cell development.

Ultrasound is widely used for many applications. For fuel cell manufacturing, it is ideal for making catalyst inks. Ultrasonic spraying is an effective method to reduce platinum loading in fuel cells. Different catalyst ink formulations and platinum loadings have different sonication protocols. In terms of cost, the optimal platinum loading must be considered along with the cost of other core components. This expanded cost analysis is a useful way to reduce the cost of fuel cell systems. In general, direct methanol fuel cells and high temperature PEMFCs require more catalyst than low temperature PEMFCs. Therefore, ultrasonic spray technology has great potential in the fabrication of direct methanol fuel cells and high temperature PEMFCs.

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.