SOFC Electrolyte Materials

SOFC Electrolyte Materials – Ultrasonic Spray Coater – Cheersonic

Everything you want to know about SOFC electrolyte materials is here!

Solid oxide fuel cell (SOFC) is an all-solid-state chemical power generation device that can convert chemical energy stored in fuel and oxidant into electrical energy at medium and high temperature. It has broad application prospects in the fields of large power plants, automobile backup power, aerospace and chemical industry.

Electrolyte materials are one of the important components in all components of SOFC. As a core component, its main function is to conduct ions and form a conductive path between the cathode and the anode. Solid oxide fuel cells have relatively high requirements for electrolytes, and generally should have the following characteristics:

(1) High ionic conductivity (greater than 0.1S/cm at 1000°C) and negligible electronic conductivity (less than 10-3S/cm at 1000°C) at operating temperature, which can maintain the battery’s work smoothly;

(2) It should have certain stability and good compactness under oxidizing atmosphere and reducing atmosphere;

(3) The electrolyte should match the thermal expansion coefficient of the anode and the cathode, so that the electrolyte and the electrode are in good contact to avoid cracking and falling off;

(4) Higher mechanical strength and lower price.

Electrolyte materials can be divided into oxygen ion conduction type and proton conduction type according to the ions that can be conducted. Commonly used SOFC oxygen ion conductors include fluorite structures (materials based on ZrO2, CeO2 and Bi2O3) or perovskite structures (such as materials based on LaGaO3). The doped barium ceria and doped barium zirconate are high temperature proton conductors that have developed rapidly in recent years.

Electrolyte material classification

1. Oxygen ion conduction type

Generally, oxygen-ion solid electrolytes are made of oxygen-deficient fluorite or perovskite oxides, which allow oxygen ion transport through oxygen vacancies. Fluorite-type oxides are currently the most widely used electrolyte materials in SOFCs.

1.1 Oxide electrolyte with fluorite structure

Fluorite structure oxides are simple cubic lattices composed of anions in a face-centered cubic close-packed cation lattice, anions occupy all tetrahedral voids, and all octahedral voids are empty. Diffusion in the lattice provides transport channels. From the historical point of view of the development of ionic research, oxygen ion conductors with fluorite structure are the earliest and most in-depth study of oxygen ion conductors, and their main types are ZrO2-based electrolytes, Bi2O3-based electrolytes and CeO2-based electrolyte materials.

(1) ZrO2-based electrolyte

Among the oxygen ion solid electrolytes, ZrO2-based solid electrolyte is one of the earliest SOFC electrolytes studied, and it is also the most widely used electrolyte material in high temperature SOFC. Y2O3 is the most commonly used dopant for ZrO2-based solid electrolytes. Yttria-stabilized zirconia (YSZ) exhibits high-strength mechanical properties, good chemical stability, and high ionic conductivity in both reducing and oxidizing atmospheres, and is the most widely used solid electrolyte material in HT-SOFC. However, the main problem of ZrO2-based electrolytes is that their electrical conductivity gradually decreases with the decrease of temperature, which limits their application in medium-temperature solid oxide fuel cells.

(2) CeO2-based electrolyte

CeO2 is also a ceramic material with a fluorite structure, which can work stably in the temperature range of 500-700 °C. Compared with ZrO2-based electrolytes, CeO2-based electrolytes have higher ionic conductivity.

Pure CeO2 is a mixed conductor of ions and electrons and is not suitable as an electrolyte. However, if CeO2-based oxides are doped with low-valent alkaline earth or rare earth oxides, it can effectively increase the oxygen ion vacancies in the system, forming solid solutions with high ionic conductivity and low conductivity activation energy. The conductivity of CeO2-based electrolyte at medium temperature is much larger than that of YSZ under the same conditions. Currently, doped CeO2-based electrolytes are promising for use in mid-low temperature SOFCs.

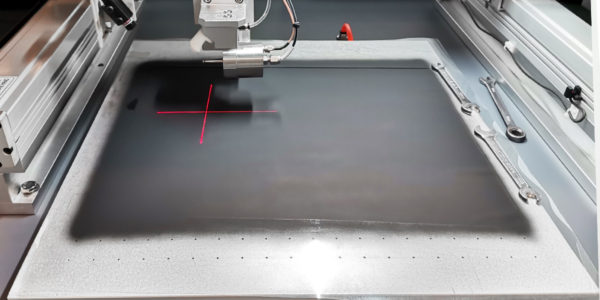

picture

(3) Bi2O3 based electrolyte

Among various solid electrolyte materials, Bi2O3-based electrolyte materials have the highest ionic conductivity and have lower interfacial resistance with electrodes compared with ZrO2 electrolytes. However, Bi2O3-based electrolyte materials are easily reduced under low oxygen partial pressure, and are thermodynamically unstable at temperatures below 700 °C. In addition, the oxygen partial pressure range for ion conduction is small, and Bi2O3 is easily reduced under low oxygen partial pressure. Therefore, how to maintain the stability of Bi2O3 in the low oxygen partial pressure range is the focus of future research.

1.2 Oxide electrolytes with perovskite structure

Perovskite structure (ABO3) oxides have mixed ion-electronic conductivity and are good electrolyte materials. LaBO3 (B=Al, Sc, Ga, Y, etc.) perovskites exhibit high oxygen ion conductivity at moderate temperatures, among which LaGaO3-based solid oxides are the most studied perovskite oxide electrolytes.

1. 3. Electrolytes of other structures

Electrolytes of other structures include pyrochlore-type electrolytes (such as Ln2Ti2O7), mayorite-type electrolytes (such as Ba2In2O5;) and non-cubic oxides (such as La10Si6O27), etc., but due to insufficient stability, low electrical conductivity, and electronic conductivity Or other various problems, there is still a big gap from commercial application, so further research is needed.

2. Proton Conductive Type

In addition to oxygen ions, proton-conducting oxides can also be used as electrolytes for intermediate-temperature SOFCs. Because protons are the smallest positive ions, their mobility is high, and high ionic conductivity can be obtained at low temperatures. SOFCs with proton-conducting oxides as electrolytes have also been extensively studied in the past few decades, among which doped BaCeO3 materials have the highest proton conductivity and have received extensive attention. However, doped BaCeO3 is unstable in acidic atmosphere (CO2, SO2) and easy to decompose. After introducing some oxides to improve its stability, its proton conductivity will drop significantly. These factors restrict the further development of doped BaCeO3 electrolytes. application. Other proton conductor oxides include doped BaZrO3, rare earth doped LaNbO4, doped La2Zr2O7, etc., which are difficult to be further applied due to low proton conductivity or poor stability.

Summarize

As an efficient and clean energy conversion device, SOFC is recognized as a revolutionary green energy technology in the 21st century. Electrolyte is the core component of SOFC, and it is very important in the development of SOFC’s low temperature. Doping to improve existing electrolytes is a common approach to increase oxygen vacancy concentration, increase ionic conductivity, and reduce battery operating temperature. At present, the research on electrolytes is still in the early stage of development, and the main problem to be solved is to improve the ionic conductivity of electrolyte materials, while improving chemical stability and avoiding reduction.

Source: DT New Energy

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.