Progress and Trend of Hydrogen Production by Electrolysis of Water

Progress and Trend of Hydrogen Production by Electrolysis of Water – Cheersonic

The promotion and application of hydrogen in energy storage, chemical industry, metallurgy, distributed power generation and other fields has become one of the effective ways to control greenhouse gas emissions and slow the rise of global temperature. Adhere to the original intention of green utilization of hydrogen energy, actively develop green hydrogen production technology represented by PEM electrolysis of water to produce hydrogen, and realize the integrated development with renewable energy.

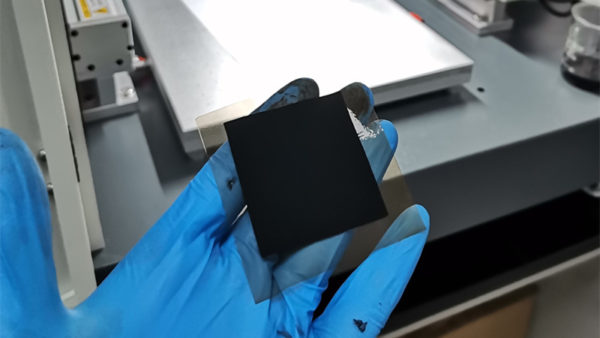

PEM water electrolysis hydrogen production technology has the characteristics of high operating current density, low energy consumption, high hydrogen production pressure, adaptability to renewable energy power generation fluctuations, and compact footprint, and has the basic conditions for industrialization and large-scale development. To this end, it is suggested to start with key materials and components such as electrocatalysts, membrane electrodes, and bipolar plates, and reduce costs through production capacity improvement and technological progress, thereby supporting the steady decline in the comprehensive cost of PEM electrolysis for hydrogen production; improving catalyst activity and increasing The utilization rate of catalysts can effectively reduce the amount of precious metals; the electrode structure with efficient mass transfer is developed to further improve the operating current density of PEM electrolysis; the material properties and surface technology of bipolar plates are improved, and corrosion resistance is improved while reducing costs.

With the rapid development of renewable energy sources such as wind, light, and water, it is expected that the technology and application of electrolysis of water for hydrogen production will enter a period of steady growth. To this end, suggestions: increase the use of renewable energy for the demonstration of PEM water electrolysis for hydrogen production; combine commercial promotion to comprehensively reduce the cost of PEM water electrolysis for hydrogen production, adapt to the large-scale development of renewable energy; conduct large-scale electrolysis In the application of water-based hydrogen production equipment, high-pressure hydrogen is mixed and sent to the natural gas pipeline network, and hydrogen is taken from the natural gas pipeline in the area where hydrogen is used. Hydrogen is extracted from the gas, and when the hydrogen concentration is lower than 5%, the hydrogen production method of mixed gas reforming is adopted, which does not increase the CO2 emission, but also has the technical feasibility of long-distance hydrogen transportation.

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.