Perovskite Solar Cell Coating Technology

Perovskite Solar Cell Coating Technology – Spray Technology – Cheersonic

Perovskite solar cells (perovskite solar cells): It is a solar cell that uses a perovskite-type organic metal halide semiconductor as a light-absorbing material. It belongs to the third generation of solar cells and is also called a new concept solar cell.

As a synthetic material, perovskite was first tried in the field of photovoltaic power generation in 2009. Because of its excellent performance, low cost and huge commercial value, in recent years, the world’s top scientific research institutions and large multinational companies have invested a lot of manpower Material resources, and strive to achieve mass production as soon as possible.

However, most solar cells face the same problem in production, no matter how the material is, how to carry out the coating process on the surface of the cell.

All current technical methods cannot well solve the problem of uniformity of the coating film layer. In the coating process of ordinary spraying method, the coating solution in the spray center is enriched, causing mottling; the surface etching method is difficult to uniform due to the surface composition of the embossed glass, resulting in inconsistent etching reaction speed and uneven film thickness; even if the uniformity of roller coating However, it is difficult to achieve high-precision consistency due to the constraints of various factors such as glass thickness difference and roller table transmission vibration.

If the uniformity of the coating cannot be further improved, on the one hand, the color difference of the component will affect the appearance, and on the other hand, the hot spot effect will be caused by the inconsistent light transmittance of each area of the coated glass, which will affect the durability of the component.

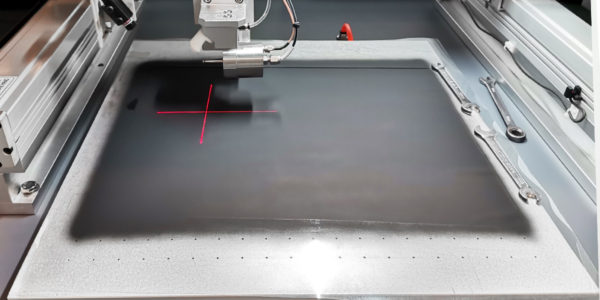

In response to this problem, after years of exploration, Cheersonic provides an ultrasonic coating system, which integrates multiple systems, such as ultrasonic, carrier gas, heating stage, vacuum adsorption and exhaust gas discharge, and can be applied to a full range of ultrasonic nozzles. Ultrasonic coating equipment combined with new spray and control technology can achieve more uniform, thinner and more controllable film coating.

Chinese Website: Cheersonic Provides Professional Coating Solutions