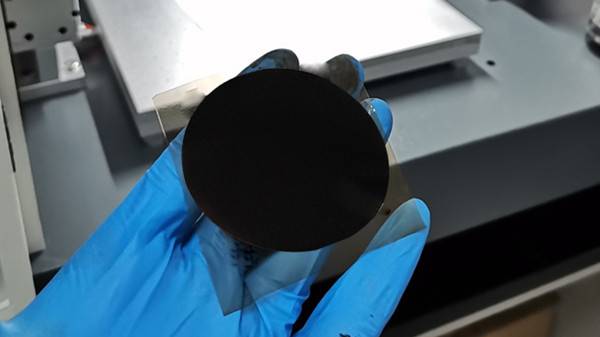

Electrode for Preparing Hydrogen Peroxide by Ultrasonic Spraying

1. High coating uniformity: Ultrasonic spraying can spray the electrode material evenly on the electrode surface to form a uniform coating. This helps to increase the active surface area of the electrode and make the reaction sites on the electrode surface more evenly distributed, thereby improving the reaction efficiency of the electrode and the generation rate of hydrogen peroxide. Compared with traditional spraying methods, ultrasonic spraying can better control the thickness and uniformity of the coating, reduce the difference in coating thickness, and improve the consistency of electrode performance.

2. Accurate thickness control: The thickness of the electrode coating can be accurately controlled, and the spraying parameters can be adjusted according to different process requirements and electrode designs to achieve the required coating thickness. Accurate thickness control helps to optimize the performance of the electrode and avoid performance degradation or material waste caused by too thick or too thin coating. For example, when studying new electrode materials, accurate ultrasonic spraying technology can help scientists accurately explore the effects of different coating thicknesses on the hydrogen peroxide preparation process.

3. Good adhesion: The coating formed by ultrasonic spraying has good adhesion to the electrode surface. In the process of preparing hydrogen peroxide, the electrode needs to withstand the immersion of electrolyte and the physical stress during the reaction process. Good adhesion can ensure that the coating is not easy to fall off or damage during long-term use, maintain the stability and durability of the electrode, and extend the service life of the electrode.

4. High material utilization: During the ultrasonic spraying process, the electrode material can be fully utilized, reducing the waste of materials. Compared with some traditional coating methods, ultrasonic spraying can more effectively spray materials onto the electrode surface, improve the utilization rate of materials, and reduce production costs. In addition, for some expensive electrode materials, high material utilization is particularly important.

5. Applicable to a variety of materials: Ultrasonic spraying technology is applicable to a variety of electrode materials, including metals, metal oxides, composite materials, etc. This allows researchers to select suitable electrode materials for spraying according to the specific needs of hydrogen peroxide preparation to optimize the performance of the electrode and the production efficiency of hydrogen peroxide. For example, materials with high catalytic activity can be selected to increase the reaction rate, or materials with good conductivity can be selected to reduce resistance loss.

6. Easy to operate and control: Ultrasonic spraying equipment is relatively simple to operate, and it is easy to control the parameters in the spraying process, such as spraying speed, spraying amount, atomization degree, etc. This allows operators to make adjustments based on actual conditions to achieve the best spraying effect and electrode performance. At the same time, ultrasonic spraying equipment usually has a high degree of automation, which can achieve continuous and stable spraying operations and improve production efficiency.

7. Environmental protection and energy saving: No organic solvents or other harmful chemicals are required during ultrasonic spraying, which reduces pollution to the environment. In addition, compared with some traditional spraying methods, ultrasonic spraying usually has lower energy consumption, which meets the requirements of energy saving and environmental protection.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions