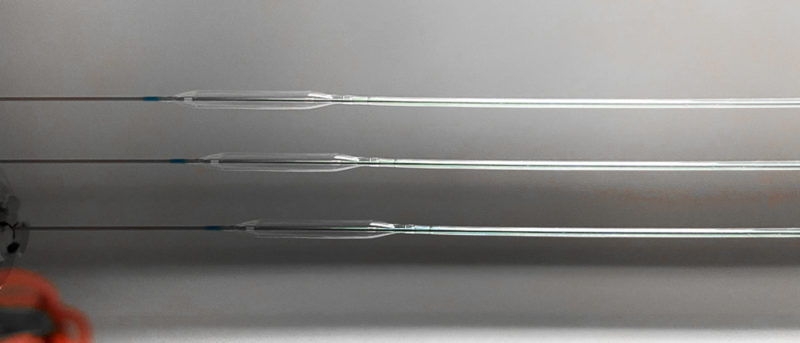

Different characteristics of PTCA balloon

Each company’s PTCA balloons have various characteristics, such as balloon size, materials used, construction, and compliance of the balloon to the vessel lumen. Depending on the location and severity of the lesion, PTCA is required to have different properties and characteristics.

PTCA balloons are divided into compliant, non-compliant and semi-compliant balloons according to their compliance.

Semi-compliant PTCA balloon for pre-dilation of lesions before stent implantation;

Non-compliant balloon catheters are usually high-strength balloons used to dilate calcified lesions and stents;

Compliant balloons are low pressure balloons sized to fit the lumen of the vessel.

PTCA balloons are also available in various materials, such as TPU, PA, PE, POC and PET.

POC is used as a balloon material due to its good tensile strength and compressibility, allowing the balloon to rapidly inflate and deflate during the process.

PE is a lightweight, versatile thermoplastic polymer.

PET is a polyester used in the production of high pressure balloons

PA is undoubtedly the largest balloon in the market. This is primarily a PA advantage, as the PA is softer, easier to fold, and easier to retract the catheter or sheath. Compared to PET, PA high-pressure balloons require thicker walls for a given burst pressure, which means that PA balloons will have a larger profile when inserted into the body and through lesions than similar PET balloons. PE balloons are being used more and more because they can be expanded by volume rather than by force. These balloons are capable of stretching from 100% to 800% and are often used to completely seal off anatomy.

TPU is considered to be the most ideal balloon material due to its excellent tensile strength, blood compatibility and biocompatibility.

Other materials, such as silicone, with the appropriate coefficient of friction, pressure rating and radial force to minimize vessel damage during insertion, also have their specific usage scenarios.

Source: MedTF

The Balloon Catheter Coating System is a special spray system designed for drug eluting balloons that provides a uniform drug coating to the balloon catheter through ultrasonic spray technology. Ultrasonic Coating System can also be used to adjust and control the deposition process of drug coatings for different liquid formulations. With the help of a special fixing device design, the entire balloon catheter can be sprayed with a maximum spraying length of 280 mm., It also has the functions of solvent doping, pre-heating, humidity control, and drying. The equipment has the characteristics of precise application amount, uniform film layer, and high utilization rate of chemical liquid. Cheersonic has extensive experience in surface coating of implantable medical devices (such as drug stents and balloons), and can provide customers with complete solutions.

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.