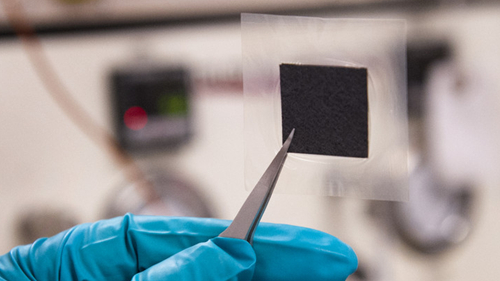

Catalyst Coated Membrane Technique

Useing of an ultrasonic spray for the fabrication ultra-low Pt loading MEAs with the catalyst coated membrane technique. Cathode Pt loading coated with catalyst ink by the ultrasonic spray method was investigated. It was determined that 0.272 mgPt/cm2 showed the best performance for 33 wt% Nafion content in a catalyst coated membrane when it was ultrasonically spray coated with SGL 24BC gas diffusion layer. The various cathode Pt loading and Nafion content ratio had been tested in this work. It was found that lower Pt loading favor lower Nafion content ratio. It was also found that at Pt loadings of 0.232 and 0.155 mgPt/cm2, the cathode mass power density performance for a 20 wt% Nafion at 600 mA/cm2 current density is 1.69 and 2.36 W/mgPt, respectively. And at Pt loadings 0.232 and 0.155 mgPt/cm2, the cathode mass power density performance for 20 wt% Nafion cathode at peak power is 2.16 and 2.93 W/mgPt, respectively.

In other literature, the cathode mass power density is higher than this work when Pt loading is lower than 0.1 mgPt/cm2. Although these cases reduced the cost of catalyst (about 20%), increasing the total cost. And the total cost increasing means the other components in fuel cells (membrane, gas diffusion layer and bipolar plate) is increasing due to lower performance need more cells to keep the same power output. This work performed similar cathode mass power density with other literature, even those tested under oxygen oxidant or back pressure for Pt loading higher than 0.1 mgPt/cm2.

And these results implied that the cathode power mass density under the same operation conditions is higher than other literature results in this work. The higher cathode mass power density could contribute to the optimization of Nafion content ratio and catalyst coated membrane technique in this paper.

Further improvement in the cathode mass power density may be achieved by either decreasing the cathode Pt loading or ink formula. This study presents the first results demonstrating high cathode mass power density and fuel cell performance with air oxidant and ambient pressure. Further study (e.g., HT-low RH, conditions, AC impedance tests) will be reported in the future.