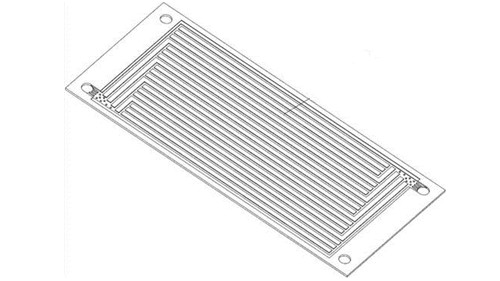

Bipolar Plate Of Fuel Cell Stack

Proton exchange membrane fuel cell (PEMFC) is a power generation device that directly and continuously converts chemical energy in fuel and oxidant into electrical energy. Proton exchange membrane fuel cells have many advantages such as high energy conversion efficiency, low pollution, simple structure, and low power generation efficiency affected by load changes. Therefore, they have broad application prospects in the future on-board driving power supplies, portable power supplies, and household power stations. , Is considered to be the clean and efficient power generation technology of choice in the 21st century. At present, the main obstacle hindering the commercial development of proton exchange membrane fuel cells is their high manufacturing cost. The bipolar plate is one of the key components of the fuel cell stack. Its quality directly determines the output power of the stack and the length of its service life. Its cost also accounts for 30%-60% of the entire battery cost. Therefore, the development of high-performance and low-cost bipolar plate materials is of great significance for the large-scale commercial application of proton exchange membrane fuel cells.

As the main component of the fuel cell, the bipolar plate functions as: collecting current, separating the oxidant and reducing agent, acting as a mechanical support and uniformly transporting the reaction medium. Therefore, the bipolar plate material is required:

(1) Good gas barrier properties, and the material should be airtight;

(2) Good corrosion resistance, including 5~85°C external atmospheric environment and 65~85°C, 200 kPa battery internal environment corrosion resistance;

(3) High electrical conductivity and thermal conductivity;

(4) Good mechanical properties;

(5) Light weight;

(6) The production and processing cost is low, and it is suitable for mass production.

Ultrasonic fuel cell spraying