Analysis of PEM Electrolysis of Water for Hydrogen Production

Analysis of PEM Electrolysis of Water for Hydrogen Production – Cheersonic

The PEM water electrolyzer uses PEM to conduct protons, isolates the gas on both sides of the electrode, and avoids the shortcomings associated with AWE’s use of strong alkaline liquid electrolytes. The PEM water electrolyzer uses PEM as the electrolyte and pure water as the reactant. In addition, the hydrogen permeability of PEM is low, the purity of the hydrogen produced is high, and only water vapor needs to be removed; the electrolyzer adopts a zero-spacing structure and has low ohmic resistance. The overall efficiency of the electrolysis process is significantly improved, and the volume is more compact; the pressure regulation range is large, and the hydrogen output pressure can reach several megapascals, adapting to the rapidly changing renewable energy power input. Therefore, PEM electrolysis of water for hydrogen production is a promising green hydrogen production technology path.

It should also be noted that the bottleneck of PEM water electrolysis for hydrogen production lies in cost and lifespan. In the cost of the electrolytic cell, the bipolar plate accounts for about 48%, and the membrane electrode accounts for about 10%. The current international advanced level of PEM is: the performance of a single cell is 2 A cm–2@2 V, the total platinum catalyst loading is 2~3 mg/cm2, the stable operation time is 60,000~80,000 h, and the hydrogen production cost is about is $3.7 per kilogram of hydrogen. Research on reducing the cost of PEM electrolyzers focuses on core components such as catalysts, PEM-based membrane electrodes, gas diffusion layers, and bipolar plates.

Electrocatalyst

Since the anode of the PEM electrolyzer is in a strongly acidic environment (pH ≈ 2) and the electrolysis voltage is 1.4–2.0 V, most non-precious metals corrode and may combine with the sulfonate ions in the PEM, thereby reducing the ability of the PEM to conduct protons. The electrocatalyst research of PEM electrolyzer is mainly about Ir, Ru and other noble metals/oxides and their binary and ternary alloys/mixed oxides, supported catalysts with titanium material as carrier.

According to the technical planning goal, the total loading of platinum group catalysts on the membrane electrode should be reduced to 0.125 mg/cm2, while the current loading of the anode iridium catalyst is in the order of 1 mg/cm2, and the Pt loading of the cathode Pt/C catalyst is about 0.4. ~0.6 mg/cm2. The Ir0.7Ru0.3Ox catalyst prepared by the Italian research team can achieve an electrolytic cell performance of 3.2 A cm–2@1.85 V when the total loading of the anode catalyst is 1.5 mg/cm2.

The Ir0.38/WxTi1-xO2 catalyst prepared by the Giner company’s research team has a full battery performance of 2 A cm-2@1.75 V when the Ir loading is 0.4 mg/cm2, and the Ir content is only 1/5 of the traditional electrode. . The electrocatalytic oxygen evolution activity of Ru is higher than that of Ir, but the stability is poor; the activity and stability of the catalyst can be improved by forming a stable alloy with Ir. The Ir0.6Sn0.4 catalyst prepared by the Dalian Institute of Chemical Physics, Chinese Academy of Sciences has a performance of 2 A cm–2@1.82 V in the full electrolytic cell test; IrSn can form a stable solid solution structure, and the process of forming an alloy with Sn is improved It improves the dispersibility of Ir and helps to reduce the Ir loading.

The National Renewable Energy Laboratory of the United States and Giner have cooperated to develop a variety of metal-organic framework (MOF) material catalysts, and the price is only 1/20 of the traditional catalyst [7], of which the Co-MOF-GO catalyst is at 0.01 A/cm2. With an overpotential of 1.644 V (vs. RHE), it outperforms conventional Ir catalysts in half-cell decay experiments, but full-cell tests have not yet been performed.

Limited by the requirements of the acidic environment, high anode potential, and good electrical conductivity of PEM water electrolysis for hydrogen production, the research and development of non-precious metal catalysts or non-metal catalysts is relatively difficult. Ir is dominant. A better way to reduce the cost of hydrogen production and reduce the amount of precious metal catalysts in the future is to develop ultra-low loading or ordered membrane electrodes.

Diaphragm material

In terms of PEM, currently commonly used products include DuPont Na-fion series membrane, Dow Chemical Dow series membrane, Asahi Glass Co., Ltd. Flemion series membrane, Asahi Kasei Co., Ltd. Aciplex-S series membrane, Tokuyama Chemical Co., Ltd. Neosepta-F and so on. The DSMTM membrane [8] developed by Giner has been produced on a large scale. Compared with Nafion membrane, it has better mechanical properties, thinner thickness, good dimensional stability during power fluctuation and start-up and shutdown, and the application performance of actual electrolytic cells. better.

In order to further improve the performance of PEM and reduce the cost, on the one hand, the enhanced composite scheme can be used to improve the mechanical properties of PEM, which is beneficial to reduce the thickness of the membrane; on the other hand, the membrane resistance and electrolytic energy can be reduced by increasing the ionic conductivity of the membrane. It is beneficial to improve the overall performance of the electrolytic cell. Domestic PEM products have entered the trial stage.

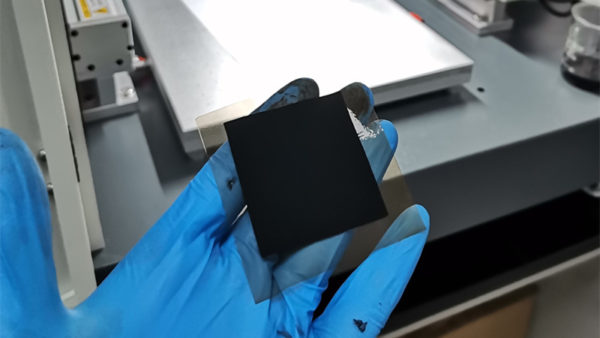

Membrane electrode

The anode of PEM electrolyzed water needs to be resistant to acid environment corrosion, high potential corrosion resistance, and should have a suitable hole structure to allow gas and water to pass through. Limited by the reaction conditions of PEM water electrolysis, membrane electrode materials (such as carbon materials) commonly used in PEM fuel cells cannot be used for water electrolysis anodes. 3M company has developed a nanostructured thin film (NSTF) electrode. The anode and cathode use Ir and Pt catalysts respectively, with a loading capacity of 0.25mg/cm2; it can work stably in an acidic environment and high potential conditions, and the rod-like array structure on the surface is conducive to improving Surface dispersibility of catalysts. Proton uses direct spray deposition to reduce catalyst agglomeration. Pt/C and Ir with a loading of 0.1 mg/cm2 and Ir O2 with a loading of 0.1 mg/cm2 are deposited on the Nafion117 membrane; the application performance of a single electrolytic cell is similar to that of traditional The high catalyst loading cell is similar (1.8 A cm–2@2V), and works stably for 500 h at 2.3 V.

Improving the performance of the current collector can also improve the performance of the electrolyzer. The research team from the University of Tennessee used template-assisted chemical etching to prepare small holes with a diameter of less than 1 mm on titanium sheets, and the thickness of the anode current collector was only 25.4 μm; the related current collector was used for PEM water electrolysis cathode, and the electrolytic performance was 2 A cm–2@1.845 V, the cathode Pt catalyst loading is only 0.086 m/cm2.

Bipolar plate

The bipolar plate and flow field account for a large proportion of the cost of the electrolytic cell, and reducing the cost of the bipolar plate is the key to controlling the cost of the electrolytic cell. In the harsh working environment of the anode of the PEM electrolytic cell, if the bipolar plate is corroded, it will lead to the leaching of metal ions, which will contaminate the PEM. Therefore, the commonly used bipolar plate protection measure is to prepare a layer of anti-corrosion coating on the surface. Letten-meier et al. prepared a Ti layer on a stainless steel bipolar plate by vacuum plasma spraying to prevent corrosion, and then prepared a Pt layer by magnetron sputtering to prevent the decrease in conductivity caused by Ti oxidation; further studies found that the Pt coating was Switching to a less expensive Nb coating maintains similar cell performance and the cell can run stably for more than 1000h. The research team of the University of Tennessee used additive manufacturing technology to make a stainless steel material flow field with a thickness of 1 mm on the cathode bipolar plate, and directly deposit a mesh gas diffusion layer with a thickness of 0.15 mm on it; the cathode impedance of the single cell is Extremely small, with cell performance up to 2 A cm–2@1.715 V, but still requires gold plating on the surface for improved stability. In addition, the Oak Ridge National Laboratory of the United States, the Korea Institute of Science and Technology and other institutions have also carried out serial research and development of bipolar plates for PEM electrolyzers.

Electrolyzer stability

In 2003, Proton completed a continuous operation test (>60,000 h) of a PEM electrolyzer with a decay rate of only 4 μV/h. The technical goal of 2030 proposed by the European Fuel Cell and Hydrogen Energy Association requires that the electrolyzer has a life of 90,000 hours, and the decay rate under continuous working conditions is stable at 0.4~15 μV/h. Many research teams have focused on exploring the attenuation mechanism of various components in the PEM electrolytic cell, and found that the shedding of catalysts and membranes, changes in water flow, and corrosion of water supply pipelines will lead to an increase in ohmic impedance. Contributing to reduced hydrogen purity, temperature/pressure changes, current density, and power duty cycling can also affect component decay rates. The Dalian Institute of Chemical Physics, Chinese Academy of Sciences conducted a 7800-h decay test on the PEM electrolyzer, and found that the pollution mainly came from the water source and metal ions of the unit components; the influence of water supply and current density changes on the performance of the PEM electrolyzer was completed.

French researchers modeled a 46 kW electrolyzer to predict operation under power fluctuations. At higher temperatures and lower pressures, the electrolyzer was most efficient and better adapted to power fluctuations.

In terms of promotion and application, China’s PEM water electrolysis hydrogen production technology is undergoing a stage change from laboratory research and development to market-oriented and large-scale application, and demonstration projects are gradually being constructed, such as the megawatt-level hydrogen energy demonstration of State Grid Anhui Electric Power Co., Ltd. The project will be completed and put into operation by the end of 2021. The joint laboratory of PEM water electrolysis and hydrogen production jointly established by Dalian Institute of Chemical Physics, Chinese Academy of Sciences and Sungrow Co., Ltd. aims at key issues in the industrialization of PEM water electrolysis technology, such as the activity and stability of inexpensive catalysts, membrane permeability, membrane Conduct research on electrode structure, etc.; for bipolar plates, diffusion layers, etc., develop cheap anti-corrosion coating technology under high current density and high voltage conditions, and focus on improving electrolysis efficiency and reducing overall costs.

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.