Development of Lithium-ion Battery Electrode Manufacturing Technology

In the field of new energy power and energy storage equipment, lithium-ion batteries occupy an irreplaceable dominant position with significant advantages such as high energy density, high power and long cycle life. With the continuous development of commercial lithium-ion batteries, the industry’s requirements for their manufacturing cost and performance are becoming more and more stringent. It should be noted that the cost and performance of lithium-ion batteries depend to a large extent on the manufacturing process of electrodes. Therefore, innovative, reliable and low-cost electrode manufacturing technology plays a vital role in promoting the large-scale application of lithium batteries.

At present, most advanced commercial lithium batteries use pulp coating to manufacture electrodes. Pulping is the process of uniformly dispersing the anode or cathode active powder, conductive agent, binder and additive in the solvent to form a stable suspension. Generally speaking, deionized water is used for the anode, while the organic solvent N-methylpyrrolidone (NMP) is often used for the preparation of cathode slurry. During coating, the prepared slurry is cast on the substrate through a slot die coater and then dried in an oven up to tens of meters long. Since the solvent needs to be evaporated in a short time, drying needs to be carried out in a high temperature environment. Affected by factors such as materials, solvents (water or NMP), and coating speed, the drying temperature usually exceeds 100°C, and this process is accompanied by a large amount of energy consumption. In addition, in the cathode manufacturing process, in view of the potential environmental hazards of NMP, an expensive and complex NMP recovery system is also required, which undoubtedly further increases the manufacturing cost.

To meet the demand for high energy density, thick electrode manufacturing has become a key development direction. However, the traditional pulp coating process has severely restricted the manufacturing of thick electrodes. The thickness of commercial electrodes is generally less than 100μm. If the pulp coating process is used to manufacture thick electrodes, the drying process is prone to uneven distribution of binders. Once the binder floats to the top of the electrode, it will directly reduce the binder content in the electrode, the cohesion between the electrode particles will deteriorate, and the adhesion between the electrode and the current collector interface will also be affected. Reduced cohesion and adhesion will further weaken the mechanical integrity of the electrode, ultimately leading to a decrease in output and a decline in production capacity.

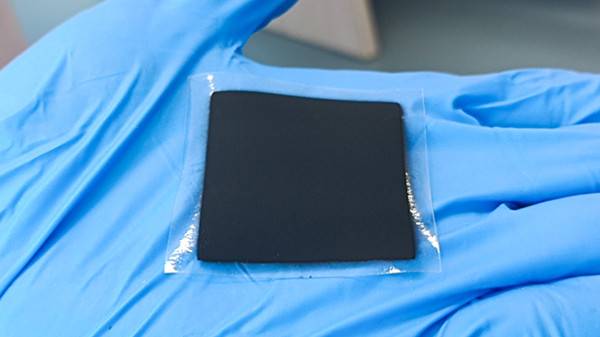

In contrast, dry electrode manufacturing under solvent-free conditions is expected to break through many limitations faced by thick electrode manufacturing. In the dry electrode process, the binder, active material and conductive additive are dried and homogenized together, which can produce thick electrodes without uneven distribution of binder. The use of electrodes with increased thickness can significantly improve energy density. As one of the most promising solutions to reduce manufacturing costs and improve electrode quality, the dry electrode process is receiving more and more attention. Its advantages are mainly reflected in the following aspects:

- Cost reduction: Since there is no need to use solvents and their related evaporation, recovery and drying equipment, the dry electrode process can significantly reduce production costs. Data shows that the production of 1 million lithium-ion batteries can save about 56% of the cost by using this process.

- Avoid electrode stratification: The dry electrode process does not require solvents, and can achieve uniform distribution of the components of the electrode material, effectively avoiding electrode stratification caused by solvent evaporation.

- Increase the loading of electrode active materials: This process is suitable for the preparation of thick electrodes, which can better control the thickness and uniformity of the electrode, especially for the preparation of ultra-high loading electrodes.

- Environmentally friendly: Solvent-free dry electrode technology can effectively reduce pollution to the environment.

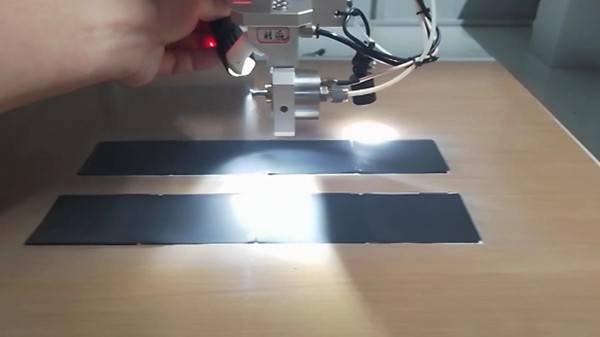

In addition to the dry electrode process, Cheersonic’s ultrasonic spraying technology also shows unique applications and advantages in the lithium-ion electrode process. Ultrasonic spraying uses the high-frequency vibration of ultrasound to atomize the slurry into extremely fine and uniform particles, and then sprays them accurately on the electrode substrate. This technology can achieve extremely thin and uniform coatings, greatly improving the consistency and performance stability of the electrode. At the same time, due to its high atomization efficiency, the slurry utilization rate is greatly improved, which reduces the waste of raw materials and indirectly reduces production costs. In the preparation of thick electrodes, ultrasonic spraying can ensure that the active material, conductive agent and binder are evenly distributed in the coating, overcome the problem of component segregation that may occur in traditional processes, and further improve the quality and performance of thick electrodes.

As a new hope for green energy, the dry electrode process has significant advantages in cost and battery performance, and has potential application prospects in other processes such as solid-state batteries and pre-lithiation. However, there are still many huge challenges in the process of process manufacturing and industrialization. For example, the bonding mechanism of dry electrode binders, category differences, long-cycle performance at the cell level, and process stability evaluation are all key issues that industry researchers focus on. In the film-forming stage of the dry electrode process, Yuanneng introduced a series of equipment such as PRCD, BER, and EIC for powder and pole-level performance evaluation, which helps optimize process ratios and improve process solutions. In addition, for the post-process section of the film-forming process, Yuanneng Technology also has relevant evaluation equipment such as electrochemical performance analysis, cell gas production, and expansion performance testing, which can evaluate and characterize the corresponding indicators, providing new support and ideas for scientific research and industrial applications.

In the continuous pursuit of high-performance, low-cost lithium-ion batteries, innovative methods such as dry electrode technology and ultrasonic spraying technology, as well as advanced equipment and technical support provided by Yuanneng Technology, are pushing lithium-ion battery electrode manufacturing technology to new heights and injecting a steady stream of power into the development of the new energy industry.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions