Ultrasonic Spray Coater for Printed Electronics

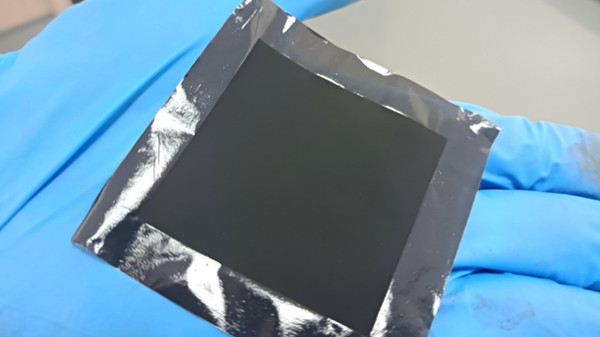

Ultrasonic spray coater for printed electronics is a specialized equipment that leverages ultrasonic energy to deposit coatings onto substrates in a precise and controlled manner. This technology is particularly suited for printed electronics, where thin, uniform layers of conductive, insulating, or protective materials need to be applied onto various substrates.

Key Advantages for Printed Electronics

- Precision and Uniformity: Ultrasonic spray coaters enable fine control of flow rate, coating speed, and deposition amount, resulting in precise and uniform coatings. This is crucial for printed electronics, where even slight variations in coating thickness can affect the performance of the final device.

- Compatibility with Diverse Materials: Ultrasonic spray coating is compatible with a wide range of materials, including conductive inks, insulating polymers, and protective coatings. This allows for the deposition of multiple layers with different properties on the same substrate, enabling the creation of complex, multifunctional printed electronic devices.

- Low-Temperature Processing: Many printed electronics require low-temperature processing to avoid damaging the substrate or the already-deposited layers. Ultrasonic spray coating can be performed at relatively low temperatures, making it suitable for heat-sensitive substrates and materials.

- Scalability: Ultrasonic spray coaters can be scaled up or down to meet the needs of different production volumes. This makes them suitable for both research and development (R&D) and large-scale manufacturing of printed electronic devices.

- Cost-Effective: Compared to other coating techniques, ultrasonic spray coating is often more economical due to its simplicity, efficiency, and low material waste.

Applications in Printed Electronics

- Conductive Tracks and Interconnects: Ultrasonic spray coaters can deposit conductive inks to form tracks and interconnects in printed circuits, enabling the creation of flexible and wearable electronic devices.

- Dielectric Layers: Insulating polymers can be sprayed onto substrates to form dielectric layers, which are essential for isolating conductive layers and preventing short circuits in printed electronic devices.

- Protective Coatings: Protective coatings can be applied to enhance the durability and reliability of printed electronic devices. These coatings can protect the device from environmental factors such as moisture, dust, and mechanical stress.

- Sensing Elements: Ultrasonic spray coating can be used to deposit functional materials for sensing elements, such as temperature sensors, pressure sensors, and gas sensors, in printed electronic devices.

Ultrasonic spray coaters are highly effective and versatile tools for printed electronics. Their precision, compatibility with diverse materials, low-temperature processing capabilities, scalability, and cost-effectiveness make them an attractive choice for manufacturers and researchers working in this field.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions