Water Electrolysis Catalyst

A water electrolysis catalyst is a substance that can accelerate the reaction rate of electrolysis water and reduce the energy required for the reaction. The following are some common water electrolysis catalysts:

1. Precious metal catalyst:

- Platinum (Pt): It is the most commonly used hydrogen evolution reaction (HER) catalyst. It has very high catalytic activity and stability. It can significantly reduce the overpotential of hydrogen generation, allowing the electrolysis of water to proceed efficiently at a lower voltage. However, platinum is expensive, which limits its widespread application in large-scale industrial production.

- Ruthenium (Ru) and Iridium (Ir): often used as catalysts for the oxygen evolution reaction (OER). Under acidic conditions, Ru and Ir oxides have good catalytic properties and can effectively promote water splitting to produce oxygen. However, they also face the problem of higher costs.

2. Non-noble metal catalysts:

- Transition metal oxides: such as manganese dioxide (MnO₂), iron oxide (Fe₂O₃), cobalt oxide (Co₃O₄), etc. These oxides have rich oxidation states and variable electronic structures, which can provide multiple active sites and promote water splitting reactions. Among them, manganese dioxide shows good OER catalytic activity under alkaline conditions, has a relatively low cost, and has certain application prospects.

- Transition metal sulfides: such as molybdenum disulfide (MoS₂), tungsten disulfide (WS₂), etc. This type of material has a similar layered structure, and the weak interactions between layers make it have better electron transport properties in catalytic reactions. Molybdenum disulfide has certain catalytic activity in the HER reaction, and its catalytic performance can be further improved by structural regulation and surface modification.

- Transition metal phosphides: such as nickel phosphide (Ni₂P), cobalt phosphide (CoP), etc. Transition metal phosphides have high conductivity and good catalytic activity, and show good HER and OER catalytic properties in alkaline electrolysis water systems. Through reasonable design and preparation methods, its morphology and structure can be controlled and its catalytic efficiency can be improved.

- Amorphous alloy catalyst: Compared with crystalline alloys, amorphous alloys have unique structural and electronic properties, such as higher surface energy, more active sites and better corrosion resistance. For example, amorphous nickel-boron (Ni-B) alloy has good catalytic activity in water electrolysis reaction.

3. Composite catalyst:

- Metal-metal oxide composite catalyst: Combining precious metals with transition metal oxides to form composite catalysts can give full play to the high catalytic activity of precious metals and the low-cost advantages of transition metal oxides. For example, loading platinum nanoparticles on titanium dioxide (TiO₂) can improve the stability and catalytic efficiency of the catalyst.

- Carbon-based composite catalyst: Compound carbon materials (such as graphene, carbon nanotubes, etc.) with transition metals or their compounds to prepare carbon-based composite catalysts. Carbon materials have good electrical conductivity and high specific surface area, which can improve the electron transport performance of the catalyst and the exposure of active sites. For example, cobalt nanoparticles supported on nitrogen-doped graphene can be used for efficient water electrolysis catalysis.

4. Bifunctional catalysts: Catalysts that can catalyze HER and OER reactions at the same time are called bifunctional catalysts. The development of efficient bifunctional catalysts is of great significance for simplifying water electrolysis devices and reducing costs. For example, some transition metal-based layered double hydroxides (LDHs) show good bifunctional catalytic performance under certain conditions.

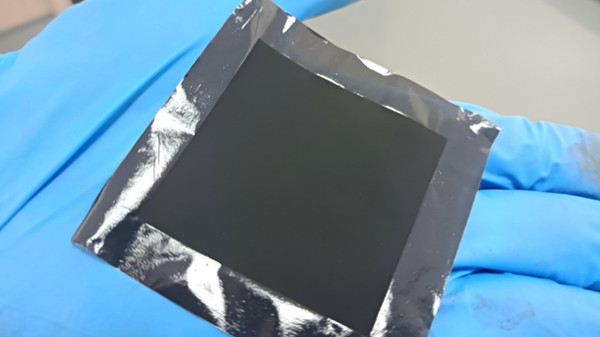

Hydrogen production by electrolysis of water is the most advantageous method for producing hydrogen. Utrasonic coating systems are ideal for spraying carbon-based catalyst inks onto electrolyte membranes used for hydrogen generation. This technology can improve the stability and conversion efficiency of the diaphragm in the electrolytic water hydrogen production device. Cheersonic has extensive expertise coating proton exchange membrane electrolyzers, creating uniform, effective coatings possible for electrolysis applications.

Cheersonic ultrasonic coating systems are used in a number of electrolysis coating applications. The high uniformity of catalyst layers and even dispersion of suspended particles results in very high efficiency electrolyzer coatings, either single or double sided.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions