Ultrasonic Spraying of Quantum Dot Solution

Ultrasonic spraying of quantum dot solution is a spraying process using ultrasonic atomization technology, which involves atomizing the quantum dot solution into fine particles through an ultrasonic atomization device and uniformly coating them on the surface of the substrate to form a coating or film. The following is a detailed analysis of ultrasonic spraying quantum dot solution:

1. Principle of Ultrasonic Spraying Technology

Ultrasonic spraying technology, also known as ultrasonic spraying, is a technique that uses ultrasonic energy to disperse material solutions into small particles and uniformly cover them on a substrate through spraying. The sprayed material is first in a liquid state, which can be a solution, sol, suspension, etc. Under the action of ultrasound, liquid coating is atomized into fine particles and uniformly coated on the surface of the substrate with a certain amount of carrier gas.

2. Advantages of Ultrasonic Spraying Quantum Dot Solution

- High coating uniformity: The distribution uniformity of liquid particles atomized by ultrasonic nozzles is significantly higher than that of traditional spraying methods, thereby improving the uniformity of the coating. Usually, the uniformity of ultrasonic spray coating can reach over 95%.

- High utilization rate of raw materials: During the ultrasonic spraying process, the coating is atomized without the need for high-pressure gas, reducing liquid rebound and splashing, thereby greatly improving the utilization rate of the coating. Compared to traditional methods, the utilization rate of raw materials in ultrasonic spraying can be increased to over 90%.

- High precision coating thickness control: The ultrasonic nozzle has no pressure on the liquid and can control the flow rate of atomized coating liquid through a high-precision metering pump, achieving high-precision coating thickness control.

- Thin coating thickness: the spray volume of the ultrasonic nozzle can achieve extremely low stable flow, thus forming an extremely thin dry film on the substrate. For certain nanomaterials, their dry film thickness can be as low as tens of nanometers.

- Non clogging nozzle and low maintenance cost: Ultrasonic nozzles achieve liquid atomization through ultrasonic oscillation, reducing the risk of nozzle clogging and lowering maintenance costs.

3. Application of Ultrasonic Coating Quantum Dot Solution

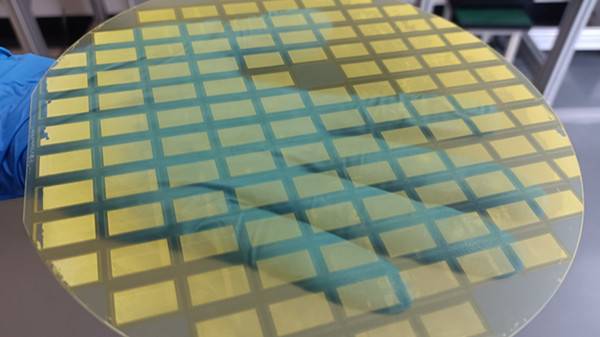

Ultrasonic spraying technology has a wide range of applications in the preparation of quantum dot thin films. Quantum dots, also known as semiconductor nanocrystals, have excellent optoelectronic properties such as high fluorescence intensity, good stability, and strong anti bleaching ability. By using ultrasonic spraying technology, quantum dot solution can be uniformly coated on the substrate to form high-quality quantum dot thin films. These thin films have broad application prospects in fields such as optoelectronics, biomedicine, and energy.

4. Preparation process of quantum dot solution by ultrasonic spraying

- Preparation of quantum dot solution: Select suitable quantum dot materials and dissolve them in appropriate solvents to form a quantum dot solution.

- Ultrasonic atomization: Inject quantum dot solution into an ultrasonic atomization device, and atomize it into fine particles through the action of ultrasonic waves.

- Spray coating: The atomized quantum dot particles are uniformly sprayed onto the surface of the substrate through a carrier gas.

- Post treatment: Heat treatment or other post-treatment processes are carried out as needed to improve the performance and stability of quantum dot thin films.

In summary, ultrasonic spraying of quantum dot solution is an efficient and uniform thin film preparation technology with broad application prospects and important research value.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions