Ultrasonic Spraying for Electrolytic Water Membrane Electrodes

Ultrasonic Spraying for Electrolytic Water Membrane Electrodes – Cheersonic

In the context of the global active search for clean energy solutions, water electrolysis hydrogen production has attracted widespread attention as a highly promising green hydrogen production method. In the water electrolysis device, the water electrolysis membrane electrode is undoubtedly the most critical core component. It integrates the dual functions of electrode and diaphragm, just like the “heart” of the entire system, and plays a decisive role in whether the water electrolysis reaction can be carried out efficiently. Next, let us explore the mystery of the water electrolysis membrane electrode and understand the innovative changes brought by ultrasonic spraying technology.

1. Basic composition and function

Composition

The water electrolysis membrane electrode is usually composed of several core parts such as catalyst layer, gas diffusion layer and diaphragm. In addition, according to actual needs, auxiliary structures such as support body or current collector are sometimes equipped. These parts work closely together, like the parts in precision instruments, to jointly promote the complex electrochemical process of water electrolysis.

Principle of action

In the working process of water electrolysis, the membrane electrode is clearly divided into the anode and cathode sides. The anode bears the heavy responsibility of oxygen evolution reaction (OER), while the cathode is responsible for hydrogen evolution reaction (HER). The diaphragm plays a dual important role here. On the one hand, it is like a loyal guard, strictly separating the oxygen produced by the anode from the hydrogen produced by the cathode, effectively avoiding serious safety hazards such as explosions that may be caused by the mixing of the two gases; on the other hand, as a “highway” for ion transmission, the diaphragm can conduct specific ions to ensure that the ion balance in the electrolyte is maintained, providing a solid guarantee for the continuous and stable advancement of the electrolysis reaction. At the same time, the catalyst layer is like an “acceleration engine” for the reaction, which can significantly reduce the overpotential of the reaction, greatly accelerate the reaction rate, and enable the water electrolysis process to operate efficiently with lower energy consumption. The gas diffusion layer is like an efficient “logistics hub”, which helps the gas products (hydrogen and oxygen) to diffuse rapidly from the catalyst layer to the gas phase space of the electrolyzer and discharge smoothly, while actively assisting the reactants in the electrolyte (such as water molecules, ions, etc.) to be quickly transported to the catalyst layer, ensuring that the electrode reaction always has sufficient “raw materials” supply.

2. Detailed introduction of each component

Catalyst layer

Function and importance

The catalyst layer is the core key of the membrane electrode, and its performance directly determines the rate and efficiency of the water electrolysis reaction. Its main mission is to significantly reduce the overpotential of hydrogen evolution reaction (HER) and oxygen evolution reaction (OER), so that these two reactions can be carried out efficiently under conditions far below the theoretical voltage. For example, without a high-performance catalyst, the actual voltage required for water decomposition will far exceed the theoretical value, which will not only lead to a large amount of energy waste, but also greatly reduce the economic efficiency of the entire process of hydrogen production by electrolysis of water. High-quality catalysts can significantly improve this situation like magic, greatly improve the practicality and economic benefits of hydrogen production by electrolysis of water, and lay the foundation for large-scale clean energy applications.

Common materials

- Hydrogen evolution reaction catalyst: In the hydrogen evolution reaction at the cathode, the precious metal platinum (Pt) and its alloys become “efficient boosters” for generating hydrogen with their extremely high catalytic activity. However, the high cost of platinum is like an insurmountable “high wall”, which seriously hinders its large-scale application. To this end, researchers have actively engaged in the exploration of non-precious metal catalysts, such as transition metal sulfides (such as molybdenum disulfide MoS₂), transition metal phosphides (such as nickel phosphide Ni₂P), etc. Through advanced modification methods such as nanostructuring and composite, the potential of these non-precious metal catalysts is continuously explored to improve their catalytic performance, making them an ideal low-cost alternative material.

- Oxygen evolution reaction catalyst: In the field of oxygen evolution reaction at the anode, commonly used catalysts include precious metal materials such as iridium (Ir) and its oxides (such as IrO₂), ruthenium (Ru) and its oxides or their complexes, which show good catalytic activity for the reaction of water oxidation to generate oxygen, and can effectively reduce the overpotential of oxygen evolution reaction. But it also faces the problem of high cost. Therefore, researchers have turned their attention to materials such as non-precious metal oxides (such as manganese dioxide MnO₂, cobalt oxide Co₃O₄, etc.) and perovskite-type composite oxides. Through in-depth research and innovative development, it is hoped that while ensuring the catalytic effect, the cost can be successfully reduced to promote the widespread application of water electrolysis technology.

Gas diffusion layer

Function and importance

The gas diffusion layer has two key missions in the membrane electrode. First, it should act like an efficient “gas transporter” to ensure that the gas products (hydrogen and oxygen) can diffuse rapidly from the catalyst layer to the gas phase space of the electrolyzer and be discharged smoothly, so as to prevent the gas from accumulating on the electrode surface and thus avoid hindering the continuous reaction. Second, it should also act as a “reactant transporter” to assist the reactants in the electrolyte (such as water molecules, ions, etc.) to be quickly transported to the catalyst layer, to ensure that the electrode reaction always has sufficient “ammunition” supply, and to maintain the stable and efficient operation of the water electrolysis reaction. For example, in the actual electrolysis process, if the gas cannot diffuse out in time, it will cover the catalyst surface like a “traffic jam”, reduce the contact opportunity between the reactants and the catalyst, and cause the reaction rate to drop sharply.

Common materials and characteristics

The gas diffusion layer usually uses porous carbon materials, such as carbon fiber paper, carbon cloth, etc. These carbon materials have many excellent properties. Good conductivity enables them to ensure efficient conduction of electrons inside the electrode; high porosity opens up abundant channels for the transmission of gas and liquid; and appropriate hydrophobicity is like a “waterproof shield” that helps prevent the electrolyte from excessively infiltrating the gas diffusion layer and ensure smooth and unimpeded gas diffusion.

Diaphragm

Function and Importance

The diaphragm plays a vital dual role in the electrolytic water membrane electrode. On the one hand, it is a “solid barrier” to ensure safety, completely separating the hydrogen and oxygen produced by the anode and cathode, eliminating the risk of safety accidents caused by the mixing of the two. On the other hand, it is a “precise channel” for ion conduction, responsible for conducting specific ions, maintaining the ion balance of the electrolyte, and providing the necessary conditions for the continued electrolysis reaction. Different types of water electrolysis systems need to be adapted to different diaphragm materials. The performance of the diaphragm is directly related to the efficiency, safety and other key aspects of water electrolysis.

Common types and characteristics

- Proton exchange membrane (used for proton exchange membrane water electrolysis): It has a unique polymer structure, and the molecular chain carries functional groups that can conduct protons (H⁺). Taking perfluorosulfonic acid membrane as an example, its sulfonic acid group -SO₃H is highly selective for protons and only allows protons to pass through, thereby accurately controlling the ion conduction path and ensuring that the electrolysis reaction is carried out efficiently and orderly. This membrane can effectively separate hydrogen and oxygen, and the hydrogen produced is extremely pure. However, its preparation process is complex, costly, and has extremely strict requirements on the quality of the inlet water.

- Anion exchange membrane (used for anion exchange membrane water electrolysis): Its molecular structure contains fixed cationic groups (such as quaternary ammonium salt groups, etc.) and movable anions (usually hydroxide ions OH⁻ can be conducted in the membrane). Relying on electrostatic interactions, the selective permeation of hydroxide ions is achieved, ensuring that the electrolysis of water is carried out smoothly in an alkaline environment. Compared with proton exchange membrane, it can use relatively cheap non-precious metal catalysts and has relatively loose requirements for inlet water quality, but the ion conductivity of some products still needs to be further improved.

- Asbestos diaphragm (commonly used in alkaline water electrolysis): It is processed from porous natural fibrous silicate minerals, with relatively low cost. It has a certain ion conductivity in the alkaline water electrolysis system and can better separate hydrogen and oxygen. However, it should be noted that asbestos is a known carcinogen, which poses serious health and environmental risks, and has certain limitations in ion conductivity efficiency and durability.

3. Preparation method of membrane electrode

Coating method

Coating method is a common preparation method. First, the prepared catalyst ink (usually the catalyst powder is evenly dispersed in a suitable solvent and binder to form a mixture with a certain fluidity) is coated on the surface of the gas diffusion layer or diaphragm by spraying, brushing or screen printing. Subsequently, after drying, hot pressing and other process steps, the catalyst layer is closely combined with the gas diffusion layer or diaphragm to finally form a membrane electrode. This method is relatively simple to operate and has low cost, making it very suitable for laboratory research and small-scale preparation. However, it also has certain limitations, and the uniformity and stability of the membrane electrode are difficult to accurately control.

Hot pressing method

The hot pressing method is to neatly stack the catalyst layer, gas diffusion layer, diaphragm and other layers of materials in a specific order, and then press them under the harsh conditions of high temperature and high pressure. Under the synergistic effect of high temperature and high pressure, the layers fit tightly together to form an integrated membrane electrode. The advantage of the hot pressing method is that it can make the bond between the layers more firm, which helps to improve the overall performance and stability of the membrane electrode. However, this method has high requirements for equipment, and the process parameters (such as temperature, pressure, time, etc.) need to be precisely controlled, otherwise a slight deviation will easily have an adverse effect on the quality of the membrane electrode.

4. factors affecting the performance of membrane electrodes

Catalyst activity and loading

The activity of the catalyst is like the power of the engine, which directly determines the rate of hydrogen and oxygen evolution reactions. The higher the activity, the faster the reaction is like an “accelerator” under the same conditions, the lower the required overpotential, and the higher the water electrolysis efficiency. At the same time, the amount of catalyst loaded on the electrode also needs to be carefully controlled. If the loading is too low, it is like insufficient troops on the battlefield, unable to provide enough active sites to promote the reaction; if the loading is too high, “crowding” may occur, leading to problems such as catalyst agglomeration, affecting its dispersion and activity, and increasing costs.

Pore structure and hydrophobicity of gas diffusion layer

The porosity, pore size distribution and hydrophobicity of the gas diffusion layer, like the condition of the traffic road, will affect the transmission efficiency of gas and liquid. The appropriate pore structure can ensure the rapid and smooth passage of gas and liquid, while good hydrophobicity can prevent the electrolyte from excessively soaking the gas diffusion layer like a “flood” and maintain the normal order of gas diffusion. Once the pore structure is unreasonable or the hydrophobicity is poor, it will be like a traffic jam, which will seriously hinder the electrolysis of water.

Ionic conductivity and stability of the diaphragm

The ionic conductivity of the diaphragm is like the speed limit of a highway, which determines the migration speed of ions between the cathode and anode, and thus has an important impact on the rate and efficiency of the electrolysis of water. In addition, the diaphragm needs to have chemical stability like a solid fortress in the complex chemical environment of water electrolysis (such as acidity, alkalinity, etc.), and can be used for a long time without degradation, damage, etc. Otherwise, it will be like a fortress being breached, which will seriously affect the service life of the membrane electrode and the safety and stability of water electrolysis.

5. Application and advantages of ultrasonic spraying in water electrolysis membrane electrodes

Application examples

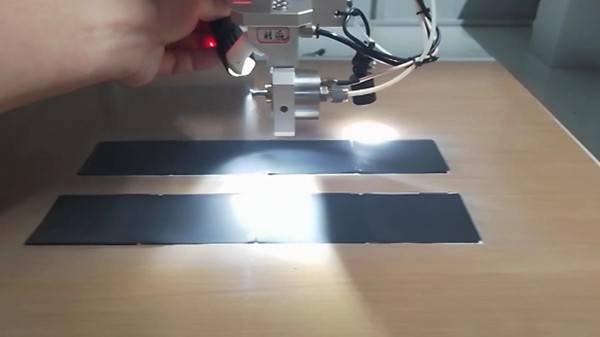

In the field of water electrolysis membrane electrode preparation, ultrasonic spraying technology has shown excellent application value. Taking the experiment of a well-known scientific research institution as an example, the institution used ultrasonic spraying technology to coat the catalyst layer when preparing proton exchange membrane water electrolysis membrane electrodes. Through the high-frequency vibration of ultrasound, the catalyst slurry is sprayed onto the surface of the proton exchange membrane in an extremely fine and uniform manner. The experimental results are surprising. Compared with the membrane electrode prepared by the traditional coating process, the membrane electrode prepared by ultrasonic spraying technology has greatly improved the uniformity of the catalyst layer thickness, the proton conductivity has increased by about 20%, and the water electrolysis efficiency has been significantly enhanced. In practical applications, this means that more hydrogen can be produced in the same time, which provides strong support for efficient hydrogen production in the energy field.

Unique advantages

Highly uniform coating

Ultrasonic spraying technology can spray the catalyst slurry on the membrane electrode surface in an extremely uniform manner, ensuring the high consistency of the catalyst layer thickness. Traditional spraying methods may cause large deviations in catalyst layer thickness due to factors such as uneven spraying pressure and inconsistent distance between the spray gun and the membrane electrode surface. Ultrasonic spraying uses high-frequency oscillation of ultrasound to evenly disperse the catalyst particles in the slurry at a very fine scale and spray them accurately to the target position. According to actual testing, the thickness deviation of the catalyst layer prepared by ultrasonic spraying can be controlled within a very small range. Compared with the traditional spraying process, the deviation is reduced by about 80%, which effectively avoids local performance differences caused by uneven coating thickness and greatly improves the overall performance stability of the membrane electrode.

Efficient catalyst dispersion

In the traditional catalyst slurry preparation and coating process, catalyst particles are prone to agglomeration, which will cause some catalyst active sites to be wrapped and unable to fully exert the catalytic effect. Ultrasonic spraying technology can efficiently disperse catalyst particles in the slurry through the powerful dispersing effect of ultrasound, so that they are evenly distributed in the form of single particles or extremely small agglomerates. In this way, during the spraying process, each catalyst particle can fully expose its active site, greatly improving the utilization rate of the catalyst. Studies have shown that the catalyst utilization rate of membrane electrodes prepared using ultrasonic spraying technology is about 30% higher than that of traditional processes. Without increasing the amount of catalyst, the rate and efficiency of water electrolysis reaction are significantly improved, which provides a possibility for reducing the cost of hydrogen production.

Mild coating process

The materials such as proton exchange membrane and anion exchange membrane in membrane electrodes are usually fragile. Traditional coating processes, such as high-pressure spray gun spraying or scraper coating, may damage the microstructure of membrane materials due to large mechanical force or high-pressure impact during operation, thereby affecting the performance and service life of membrane electrodes. Ultrasonic spraying technology uses a gentle spraying method to gently spray the catalyst slurry onto the surface of the membrane electrode with high-frequency vibration of ultrasound, avoiding mechanical damage to the membrane material. In actual production, after long-term use tests, the membrane electrode prepared using ultrasonic spraying has better integrity and ion conductivity of the diaphragm, effectively extending the service life of the membrane electrode and reducing the frequency and cost of replacing the membrane electrode.

Good material adaptability

The preparation of membrane electrodes for water electrolysis involves many different types of materials, including various catalysts, gas diffusion layer materials, and diaphragm materials. Ultrasonic spraying technology has excellent material adaptability. Whether it is for precious metal catalysts or non-precious metal catalysts, whether it is proton exchange membranes, anion exchange membranes or other new diaphragm materials, it can achieve efficient and precise coating. This enables researchers and manufacturers to choose materials more flexibly when exploring new membrane electrode materials and preparation processes, give full play to the advantages of various materials, and promote the continuous innovation and development of electrolytic water membrane electrode technology.

6. Application and development trends

Application fields

Due to its key role, electrolytic water membrane electrodes are widely used in various electrolytic water hydrogen production technologies, including proton exchange membrane electrolysis, anion exchange membrane electrolysis, alkaline electrolysis, etc. In the energy field, it provides a reliable guarantee for the hydrogen supply of fuel cell vehicles, and also plays an important role in renewable energy storage, converting excess electricity into hydrogen for storage, and realizing efficient utilization and storage of energy. In the chemical industry, such as the production of hydrogen required for processes such as synthetic ammonia and hydrogenation refining, electrolytic water membrane electrodes also play an indispensable role, contributing important forces to promoting clean energy transformation and industrial sustainable development.

Development Trend

High-performance material research and development

In the future, the key direction to improve the overall performance of membrane electrodes will be to continue to explore new catalyst materials with higher catalytic activity and lower cost, as well as diaphragm materials with better ion conductivity and stronger chemical stability, while further improving the performance of gas diffusion layer materials. Through material innovation, the efficiency and economy of hydrogen production by water electrolysis can be fundamentally improved.

Optimize the preparation process

It is imperative to study more precise, efficient and scalable membrane electrode preparation processes. This can not only improve the quality stability and consistency of membrane electrodes, but also effectively reduce the preparation cost to meet the growing demand of the water electrolysis hydrogen production industry. Innovative processes such as ultrasonic spraying technology will play an important role in optimizing the preparation process and promote the industry to a higher level.

Coupling with renewable energy

With the rapid development of renewable energy such as solar energy and wind energy, membrane electrodes need to be better adapted to the coupling application of these renewable energy power generation systems. Improving adaptability to intermittent power sources and achieving more efficient green hydrogen production will be an important trend in future development. Through this coupling, the abundant resources of renewable energy can be fully utilized to achieve clean and sustainable energy production, injecting strong impetus into the global energy transformation.

In short, as the core component of water electrolysis hydrogen production technology, the continuous optimization of water electrolysis membrane electrode performance and the continuous reduction of costs are extremely important for improving the efficiency of water electrolysis hydrogen production, expanding the application field and promoting energy transformation. The emergence of ultrasonic spraying technology has brought new vitality to the preparation of membrane electrodes, and is expected to promote greater breakthroughs in water electrolysis hydrogen production technology in the future, and contribute key forces to the development of the global clean energy industry.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions