Ultrasonic Spraying Aluminum-plastic Film Technology

Ultrasonic spraying aluminum-plastic film technology, due to its unique advantages, can be applied in multiple fields. Here are several main application areas:

Packaging industry:

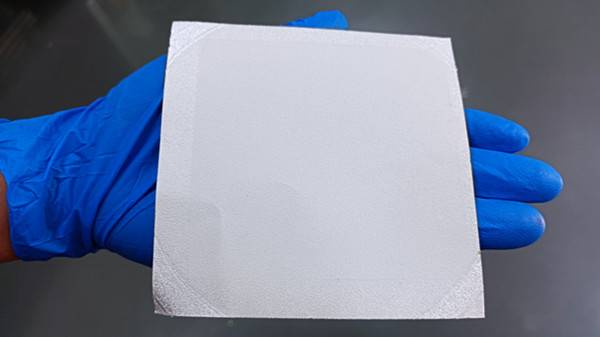

- Food packaging: Aluminum plastic film has good barrier properties, which can effectively prevent the penetration of oxygen, moisture, and microorganisms, thereby extending the shelf life of food. Ultrasonic spraying technology can form a uniform and dense aluminum-plastic film coating on the surface of packaging materials, improving the protective performance of packaging.

- Drug packaging: Drugs have extremely high requirements for packaging materials, requiring good sealing, moisture resistance, and light avoidance. Ultrasonic coating aluminum-plastic film technology can meet these requirements, ensuring the stability and safety of drugs during storage and transportation.

- Circuit board packaging: In the production process of electronic circuit boards, aluminum-plastic film is often used as a packaging material to protect the circuit from external environmental interference and damage. Ultrasonic spraying technology can form a uniform aluminum-plastic film coating on circuit boards, improving their stability and reliability.

- Electromagnetic shielding material: Aluminum plastic film has good electromagnetic shielding performance, which can effectively reduce the interference of electromagnetic radiation. Ultrasonic spraying technology can evenly spray aluminum-plastic film on the surface of components that require electromagnetic shielding, improving the electromagnetic compatibility of the product.

Construction industry:

- Building curtain wall: Aluminum plastic composite panel is a commonly used material for building curtain walls, and the quality of its surface coating directly affects the appearance and durability of the curtain wall. Ultrasonic spraying technology can form a uniform, beautiful, and durable coating on the surface of aluminum-plastic composite panels, improving the overall quality of curtain walls.

- Roof waterproofing material: Aluminum plastic film can also be used as part of the roof waterproofing material. It is sprayed onto the roof substrate through ultrasonic spraying technology to form a dense waterproof layer, improving the waterproof performance and service life of the roof.

Automotive industry:

- Car body decorative parts: In automobile manufacturing, aluminum-plastic film can be used for the manufacturing of car body decorative parts, such as wheel hub covers, door decorative panels, etc. Ultrasonic spraying technology can form a uniform aluminum-plastic film coating on the surface of these components, improving their aesthetics and durability.

- Thermal insulation material: Aluminum plastic film also has good thermal insulation performance and can be used in the manufacturing of automotive thermal insulation materials. Ultrasonic spraying technology can evenly spray aluminum-plastic film on the surface of insulation materials, improving their insulation effect and service life.

Other fields:

Medical devices: In the manufacturing of medical devices, aluminum-plastic film can be used to make components that require special protection and packaging. Ultrasonic spraying technology can ensure the uniformity and density of the surface coating of these components, meeting the high standard requirements of medical devices.

In the field of new energy, aluminum-plastic film also plays an important role in the manufacturing of new energy products such as solar panels and lithium-ion batteries. Ultrasonic spraying technology can be used for the packaging and preparation of protective coatings for these products.

In summary, ultrasonic coating aluminum-plastic film technology has broad application prospects and can play an important role in various fields such as packaging, electronics, construction, and automobiles.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions