Ultrasonic Spray Coating in Printed Electronics

Maximizing Efficiency and Precision with Ultrasonic Spray Coating in Printed Electronics

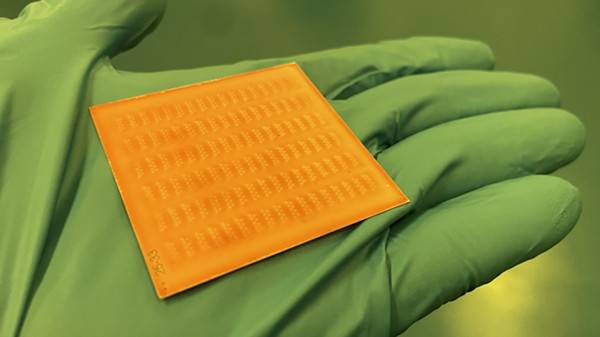

Ultrasonic spray coating stands out as a groundbreaking development in the realm of printed electronics, where the quest for precision and consistency is relentless. Leveraging high-frequency ultrasonic waves, this technology masterfully converts liquid materials into an ultra-fine mist, composed of minuscule droplets that are expertly guided onto substrates for flawless and uniform coverage with negligible overspray.

The advantages of ultrasonic spray coating in printed electronics are manifold:

– Material Versatility: This cutting-edge process excels in the application of an extensive array of materials, from conductive inks to dielectrics. The ability to handle such a diverse range of materials is instrumental in producing complex electronic patterns with unparalleled accuracy, making it indispensable for the creation of flexible circuits, sensors, and displays.

– Material Conservation: In stark contrast to conventional coating methods that often lead to substantial material waste, ultrasonic spray coating sets a new standard for efficiency. The precise control it offers over the deposition process significantly cuts down on excess material use, a cost-saving measure that is particularly valuable within the electronics industry’s cost-conscious landscape.

– Enhanced Resolution: The technology boasts an improved resolution that paves the way for the fabrication of detailed designs and features at reduced scales. This level of detail is essential for the advancement of high-performance electronic devices that rely on intricate interconnections and exact component positioning, ultimately leading to products with superior performance and functionality.

In essence, ultrasonic spray coating technology is a game-changer for printed electronics, not only streamlining the application of various materials but also pushing the boundaries of precision and waste reduction. As the drive for smaller, more powerful electronic devices intensifies, this technology is set to become an indispensable force shaping the future of the industry.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions