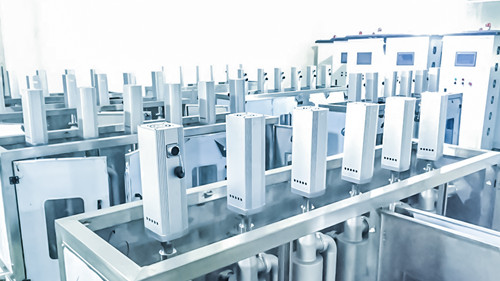

Ultrasonic Slurry Treatment

Ultrasonic Dispersion of Ceramic Slurries – Cheersonic

Ultrasound is a widely used technique to reliably and efficiently disperse and deagglomerate slurry particles. The formulation of the slurry must be properly mixed to obtain adequate wetting and dispersibility. Ultrasonic nanodispersion equipment is capable of handling high viscosity slurries and composites.

Ultrasonic nano-dispersion equipment can generate high shear forces and is an efficient solution for slurry deagglomeration and dispersion. Compared with traditional mixers and mixers, ultrasonic dispersers can effectively shorten processing time, improve quality, and ensure product consistency. Ultrasonic processors can easily handle high viscosity, bulky and abrasive materials. Through the application of ultrasonic slurry processing equipment, particles can be uniformly reduced to nanometer size and integrated into high-performance nanocomposites.

The main advantages of ultrasonic slurry particle treatment include:

Highly uniformly dispersed nanoparticles

Abrasive dispersion for processing high viscosity slurries

Save time by 90%

Processing effect is stable