The Difference Between Positive and Negative Photoresist

I think many people may have heard that the old metal body cameras (silver salt photos) have terms such as negative film and positive film. The photoresists used in photolithography also have negative and positive. Negative photoresist will leave a pattern where the light is irradiated, while positive photoresist will leave a pattern where the light is not irradiated. Therefore, for the same mask, the patterns obtained by using negative photoresist and positive photoresist are completely opposite.

Positive photoresist: The photosensitive material of positive photoresist is diazonaphthoquinone combined with phenolic resin. After exposure, the exposed part of the photoresist will undergo chemical changes and can be dissolved in the developer, while the unexposed part remains unchanged, thereby forming a photoresist pattern with the same pattern as the mask on the substrate.

Negative photoresist: Negative photoresist is composed of photosensitive material + polymer, which is further polymerized after light exposure and is insoluble in organic solvents as developer. That is to say, the exposed part of the photoresist will undergo chemical changes such as cross-linking, making this part insoluble in the developer, while the unexposed part can be dissolved, thereby forming a photoresist pattern on the substrate with the opposite pattern of the mask.

In comparison, because negative photoresist undergoes polymerization reaction, it is at a disadvantage in terms of resolution, so positive photoresist is more commonly used in advanced processes.

Resolution difference

- Positive photoresist: It usually has higher resolution and can form finer patterns. This is because its dissolution characteristics in the exposed area make the edges clearer and reduce blur and diffusion.

- Negative photoresist: The resolution is relatively low. Due to the cross-linking reaction of the exposed part, the pattern edge may not be sharp enough and a certain degree of diffusion may occur.

Contrast difference

- Positive photoresist: The contrast is higher, that is, the dissolution rate of the exposed and unexposed parts in the developer is quite different, which helps to form a clear pattern boundary.

Negative photoresist: The contrast is relatively low, and the difference in dissolution rate between the exposed and unexposed parts is not as obvious as that of positive photoresist.

Sensitivity difference

- Positive photoresist: Generally, the sensitivity is low, and a higher exposure dose is required to make the photoresist fully react.

Negative photoresist: The sensitivity is high, and a lower exposure dose can trigger a cross-linking reaction.

Application scenario difference

- Positive photoresist: Suitable for integrated circuit manufacturing with high resolution requirements, such as advanced semiconductor chip processes. It is also widely used in microelectromechanical systems (MEMS), flat panel displays and other fields to make fine structures and patterns.

- Negative photoresist: Commonly used in some occasions where the resolution requirements are not so extreme, but a higher etching resistance is required, such as some thick film lithography processes. In some special processes, such as making relief structures or requiring thicker photoresist layers, negative photoresist may be more advantageous.

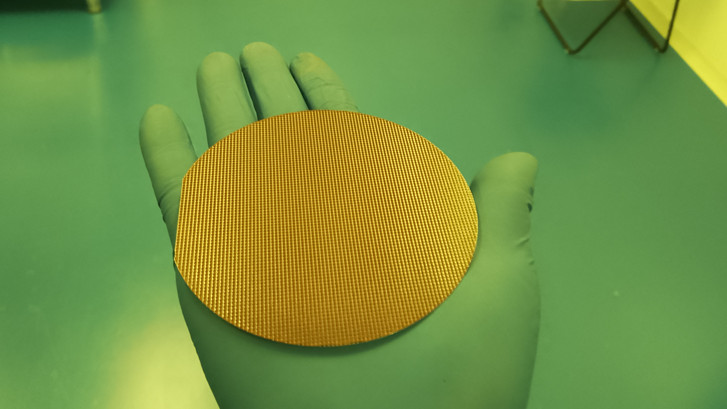

Ultrasonic spraying systems have been proven to be used in various applications that require uniform and repeatable photoresist or polyimide film coatings. The thickness control range is from submicron to more than 100 microns, and any shape or size can be coated.

Ultrasonic spraying technology is used for semiconductor photoresist coating. Compared with traditional coating processes such as spin coating and dip coating, it has the advantages of high uniformity, good encapsulation of microstructures, and controllable coating area. In the past 10 years, it has been fully demonstrated that the 3D microstructure surface photoresist coating using ultrasonic spraying technology, the prepared photoresist coating is significantly higher than the traditional spin coating in terms of microstructure wrapping and uniformity Craft.

The ultrasonic spraying system can precisely control the flow rate, coating speed and deposition volume. Low-speed spray shaping defines atomized spray as a precise and controllable pattern to avoid excessive spray when producing a very thin and uniform layer. The ultrasonic spray system can control the thickness from sub-micron to more than 100 microns, and can coat any shape or size.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions