Spraying Metal Oxides for Laboratory Research

1. In terms of spraying effect:

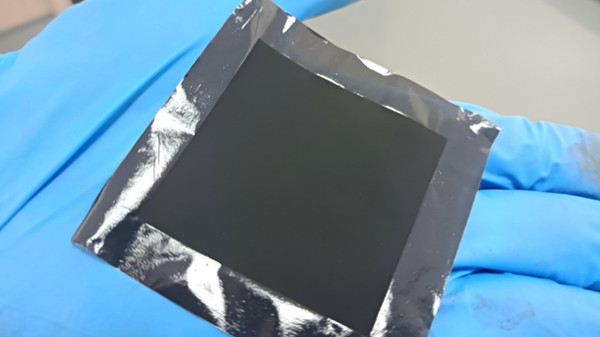

- Uniform atomization of particles: Ultrasonic spraying equipment can atomize metal oxide solutions into uniform micrometer or even nanometer sized droplets, forming a uniform thin film coating. This is very important for laboratory research to ensure the accuracy and reproducibility of experimental results. For example, when studying the optoelectronic properties of metal oxides, a uniform coating helps to obtain stable test data.

- Controllable droplet size: The droplet size can be precisely controlled according to experimental requirements, thereby controlling the thickness and structure of the coating. For different metal oxide materials and research purposes, different droplet sizes and coating thicknesses may be required, and ultrasonic spraying equipment can meet this requirement.

2. In terms of equipment performance:

- High stability: Made of high-performance materials such as titanium alloy, stainless steel, etc., it has strong adaptability and corrosion resistance, and can operate stably for a long time in laboratory environments.

- Not easy to block: When spraying metal oxide suspension, the nozzle is prone to particle blockage, which affects the spraying effect. The nozzle design of high-quality ultrasonic spraying equipment is reasonable, with self-cleaning function or special anti clogging technology, which can reduce the occurrence of nozzle clogging.

- Low energy consumption: Laboratories usually have certain requirements for equipment energy consumption. Ultrasonic spraying equipment has lower energy consumption, meets the needs of laboratory use, and does not consume too much energy during long-term experimental processes.

3. In terms of operational convenience:

- Easy to operate: The operating interface of the device should be simple and easy to understand, making it convenient for experimental personnel to operate and set parameters. Some devices are also equipped with touch screens or intelligent control systems, making operation more convenient.

- Easy to maintain: Daily maintenance is simple and does not require complex maintenance procedures or professional maintenance personnel. For example, liquids can be transported to the nozzle through gravity or low-pressure pumps, and no cooling water is required during atomization, reducing maintenance costs and difficulty.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions