Spray Pyrolysis Perovskite

Spray pyrolysis perovskite is an important material preparation technology. The following is a detailed overview of it:

I. Definition and Principle

Spray pyrolysis is a process of depositing a thin film by spraying a solution onto a heated surface, in which the components react to form compounds. In the preparation process of spray pyrolysis perovskite, a solution containing perovskite components is usually atomized into tiny droplets by a spray device and sprayed into a high-temperature environment. At high temperatures, the solvent in the droplets evaporates rapidly, and at the same time, the metal salt or precursor undergoes a thermal decomposition reaction to form a nanopowder or film with a perovskite structure.

II. The preparation process of spray pyrolysis perovskite mainly includes the following steps:

1. Solution preparation: According to the composition of the target perovskite material, select a suitable metal salt or precursor and dissolve it in an appropriate solvent to form a uniform solution.

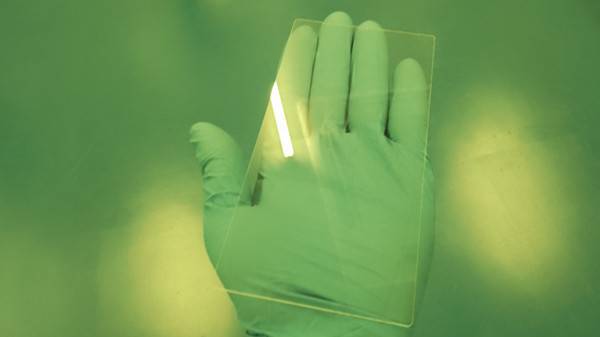

2. Spray device: Use a spray device to atomize the solution into tiny droplets. Common spray devices include ultrasonic sprayers, airflow sprayers, etc.

3. High-temperature pyrolysis: Spray the atomized droplets into a high-temperature environment, usually on a heated substrate or reaction chamber. At high temperature, the solvent in the droplets evaporates rapidly, and the metal salt or precursor undergoes thermal decomposition reaction to form nanopowders or films with perovskite structure.

4. Subsequent treatment: The prepared perovskite material is subjected to subsequent treatment as needed, such as annealing, sintering, etc., to improve its crystallinity and performance.

III. Spray pyrolysis perovskite technology has the following characteristics and advantages:

1. High efficiency: Spray pyrolysis technology can achieve rapid deposition and large-scale production, and is suitable for the preparation of large-area, uniform perovskite films.

2. Controllability: By adjusting parameters such as solution concentration, spray rate, and high temperature environment, the composition, structure, and properties of perovskite materials can be precisely controlled.

3. Low cost: The equipment and raw materials used in spray pyrolysis technology are relatively simple and cheap, which is conducive to reducing production costs.

4. Environmental protection: This technology usually uses non-toxic or low-toxic raw materials, and less waste is generated during the preparation process, which is conducive to environmental protection.

IV. Spray pyrolysis perovskite technology has broad application prospects in many fields:

1. Solar cells: Perovskite solar cells have the advantages of high efficiency, low cost, and easy preparation. Spray pyrolysis technology is one of the important methods to achieve its large-scale production.

2. Photocatalysis: Perovskite materials have excellent performance in the field of photocatalysis, and spray pyrolysis technology can prepare perovskite photocatalysts with high activity.

3. Sensors: Perovskite materials have broad application prospects in the field of sensors, and spray pyrolysis technology can prepare perovskite sensors with high sensitivity and stability.

4. Other fields: In addition, spray pyrolysis perovskite technology can also be applied to optoelectronic devices such as LEDs and lasers, as well as energy storage materials.

In summary, spray pyrolysis perovskite technology is an efficient, controllable, low-cost and environmentally friendly material preparation technology with broad application prospects in many fields. With the continuous development and improvement of technology, it is believed that it will have a broader application space in the future.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions