ULTRASONIC SPRAY DRYING

Spray drying is a technology used in the food, pharmaceutical, pigment and catalyst industries to produce small particles of controlled size. The atomized solution or slurry is introduced into the chamber as a spray. The chamber can be heated, or heated with a sprayed carrier gas, or both. As the spray solvent evaporates, the dried particles are left behind and collected. This method can be used to produce porous particles, microencapsulated particles, hollow microspheres, and agglomerated “blackberry” morphological particles. The particles can be a single composition or a composite or composite composition.

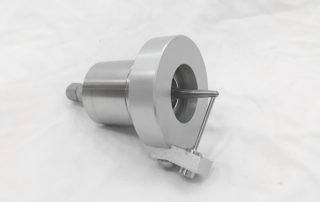

Cheersonic’s ultrasonic atomization drying equipment includes an ultrasonic power generator and a nozzle system. In addition, Cheersonic can be equipped with other ancillary equipment for spray drying systems, including heating chambers, pumps, dispersing equipment, and more.

NANO POWDER SPRAYING PYROLYSIS

Spray pyrolysis ultrasonic nozzles can be used in R&D, pilot and industrial spray pyrolysis systems to prepare ultra-fine powders. It adopts ultrasonic atomization nozzle technology, which can uniformly atomize the precursor solution or suspension and spray it into the tube furnace for high-temperature thermal decomposition to prepare ultra-fine powder, which is the key in the system of spray pyrolysis (also known as spray pyrolysis) Atomization device.

ATOMIZATION GRANULATION

Ultrasonic atomization creates a fine mist of extremely small droplets capable of coating small granules or even powders in a fluid bed process. Cheersonic enables the ultrasonic nozzle to operate in the higher temperatures of a fluid bed system while conveying the coating material in an upward direction towards the fluidized product.

Advantage:

- Tight drop/particle size distribution with high repeatability

- Profound spherical shape

- Ability to produce larger size spheres compared to typical air atomizing nozzles

- Ultrasonic vibrations virtually eliminate clogging

- Choice of sphere size based on frequency (60 kHz, most common configuration)

To reach our anytime via email please fill out the form below with your request and a company representative will reply to you. To find your local CHEERSONIC representative to connect directly click your region in the contact drop down menu.

Contact CHEERSONIC For immediate assistance please contact us the corporate headquarters during business hours at 6:00 am – 22:00 pm.

Tel: 0571-87910406

- Mobile: +86 13588732518

- Email: Market2@cheersonic.com

Add: 11-13 Chuangye Road, Changkou, Fuyang, Hangzhou, Zhejiang, China