Medical Dressing Products

The growth rate of the high-end medical dressing market continues to accelerate. Although the cost of use is relatively high, the new high-end medical dressing can shorten the wound healing time, reduce the amount of medical dressing, and greatly shorten the nursing time. Therefore, the demand for high-end dressings is increasing year by year, and the market is broad.

Classification of medical dressings

Medical dressing products mainly refer to wound coverings, which can replace damaged skin and act as a temporary barrier during the wound healing process to avoid or control wound infection and facilitate wound healing. According to different sources, it can be divided into natural materials, synthetic materials, medicinal dressings, and fixed dressings.

With the rapid development of the pharmaceutical and biological industry and the rapid innovation of products in the medical beauty market, collagen materials are widely used in dressings with their excellent properties. Collagen dressings not only play the role of traditional dressings to protect wounds and avoid infection, but also accelerate skin repair and promote the growth of epidermal cells. At present, most of the collagen dressings on the market are animal dressings (using animal-derived collagen as the raw material).

Hemostatic sponge is a dense, porous, positively charged hemostatic material. When it comes into contact with human blood, it can immediately adhere and aggregate platelets, thereby causing blood to form thrombus, block wounds, and release various coagulation-related substances. Factors, under the combined action of endogenous and exogenous coagulation pathways, make blood form stable fibrin polymers, thereby forming blood clots and achieving the purpose of wound hemostasis.

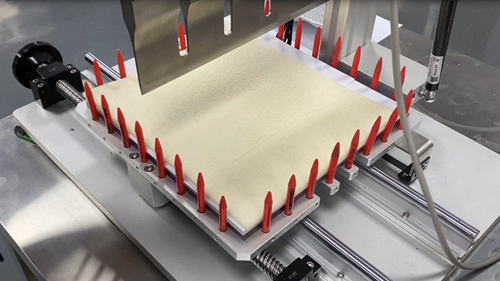

Because of its special function and special material, the hemostatic sponge has the characteristics of high elasticity, strong toughness, and long exposure time, so it is difficult to be processed by traditional mechanical cutting. Ultrasonic cutting avoids the shortcomings of traditional mechanical cutting to a certain extent, and can cut the hemostatic sponge at various angles and directions, and the hemostatic sponge is still smooth and smooth after cutting.

Ultrasonic vibration reduces the frictional resistance between the blade and the hemostatic sponge, so that the blade can cut the hemostatic sponge smoothly without deformation, and there will be no burnt cut surface. Ultrasonic vibration reduces material sticking on the blade, thereby reducing downtime in cleaner production systems. Throughout the cutting process, the blade surface remains smooth, clear and clean.