Mechanism And Characteristics Of Hydrogel Medical Dressings

Mechanism And Characteristics Of Hydrogel Medical Dressings – Cheersonic

Hydrogel medical dressing is a new type of wound dressing developed in recent years. It is mainly composed of a colloidal substance with a three-dimensional three-dimensional network structure after water absorption and swelling of high molecular polymer, and its water content can reach more than 90%, so as to maintain the moist environment of the wound surface.

Hydrogel medical dressings are widely used in the treatment of various wounds. Because of the unique cold compress effect of hydrogel itself, it can significantly reduce postoperative pain and inflammation, shorten the time of wound healing, and promote better wound healing without leaving scars; moreover, its translucent properties are beneficial to Observation of wounds. Including hydrogel materials for wound dressings, hydrogel materials for cartilage defect repair, hydrogel materials for periodontitis treatment, etc.

Due to its water absorption and wound soothing properties, hydrogels are especially suitable for some common wounds, such as abrasions, scratches, bedsores, laser treatments, chemical injuries, and other skin surface wounds. For these wounds, traditionally, doctors usually use sterile gauze and topical antibiotics to treat them. The gauze is easy to adhere to the skin wound tissue, and the new epithelium and granulation tissue are often destroyed when dressing is changed, causing bleeding and causing unbearable pain to the patient. The hydrogel dressing is applied to the wound, which can not only avoid wound adhesion, but also kill various bacteria, thereby avoiding wound infection.

Hemostatic sponge is a dense, porous, positively charged hemostatic material. When it comes into contact with human blood, it can immediately adhere and aggregate platelets, thereby causing blood to form thrombus, block wounds, and release various coagulation-related substances. Factors, under the combined action of endogenous and exogenous coagulation pathways, make blood form stable fibrin polymers, thereby forming blood clots and achieving the purpose of wound hemostasis.

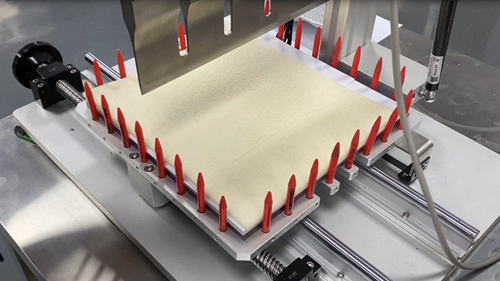

Because of its special function and special material, the hemostatic sponge has the characteristics of high elasticity, strong toughness, and long exposure time, so it is difficult to be processed by traditional mechanical cutting. Ultrasonic cutting avoids the shortcomings of traditional mechanical cutting to a certain extent, and can cut the hemostatic sponge at various angles and directions, and the hemostatic sponge is still smooth and smooth after cutting.

Ultrasonic vibration reduces the frictional resistance between the blade and the hemostatic sponge, so that the blade can cut the hemostatic sponge smoothly without deformation, and there will be no burnt cut surface. Ultrasonic vibration reduces material sticking on the blade, thereby reducing downtime in cleaner production systems. Throughout the cutting process, the blade surface remains smooth, clear and clean.