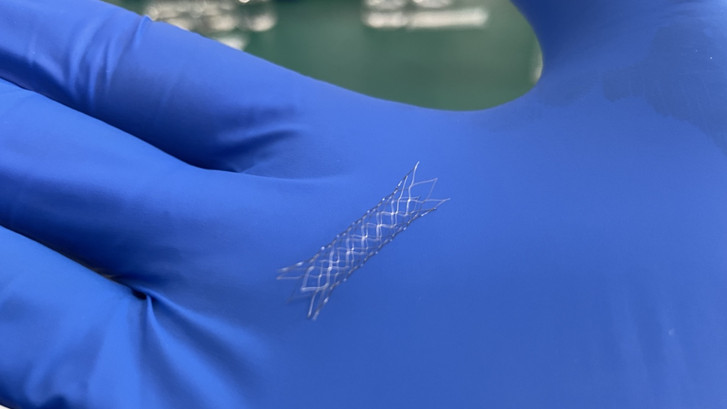

Intracranial Stent

Cerebrovascular disease (stroke) is a group of common diseases in the elderly. Because of its high morbidity, disability and mortality, it brings huge mental pressure and heavy economic burden to individuals, families and society. Survivors also often face a series of neuropsychiatric symptoms such as physical dysfunction, vision, hearing loss, cognitive decline and emotional personality changes, and also have to bear the heavy psychological burden caused by physical diseases. Severe sequelae often significantly reduce the independence of life of survivors of cerebrovascular disease, and significantly reduce the quality of life of patients and the ability to adapt to the natural and social environment. With the extension of life expectancy and the acceleration of population aging in my country, the incidence and prevalence of cerebrovascular diseases are increasing year by year. Therefore, finding an effective prevention and treatment method for cerebrovascular disease is a major issue faced by medical workers.

Endovascular intervention technology is a newly developed method to prevent and treat cerebrovascular diseases. Compared with traditional treatment methods for cerebrovascular diseases, it has certain advantages. However, interventional technology is an invasive operation after all and has certain complications. Therefore, whether the operator has the relevant professional knowledge, operational skills and experience will affect the success or failure of the interventional operation.

Classification of intracranial stents

1. Vascular stents are divided into metal tantalum, medical stainless steel and nickel-titanium alloy according to the material. Metal stents have achieved remarkable curative effects after clinical treatment, but they are prone to thrombosis, high restenosis rate, and damage to the vessel wall. In view of the above deficiencies, at present, a covered stent and a biomaterial stent have been developed. An ideal metal vascular stent should be consistent with the repair time of vascular function. Magnesium-based alloys and iron-based alloys are degradable and have good vascular support, which can effectively reduce stent restenosis.

2. Vascular stents can be divided into two types: self-expandable and balloon-expandable according to the way they are deployed in the blood vessel. The former, such as Z-shaped stents and mesh-shaped stents, can self-expand in blood vessels. The latter is inelastic by itself, and is attached to the blood vessel by expanding the balloon to a certain diameter.

3. Vascular stents can be divided into bare type, coated type and covered type according to the surface treatment. The bare surface is only polished; the coated type is coated with heparin, titanium oxide and other substances on the metal surface; the coated type is coated with a degradable or non-degradable polymer film on the outside of the metal stent.

4. Vascular stents can be divided into simple supporting stents and therapeutic stents according to their functions. Therapeutic stents include stents coated with drugs on the surface of the stent or stents or radioactive stents that use the coating outside the stent to carry therapeutic substances.

Cheersonic provides a variety of ultrasonic coating equipment and solutions for manufacturing industry of implantable, in interventional medical devices, the drug-eluting stents and balloon catheters. Our ultrasonic coating systems have been used to spray anti-restenosis drug eluting polymer solutions onto implantable stents. Compared to conventional two-fluid nozzles, ultrasonic nozzles can spray a more uniform drug coating that completely covers the stent without the orange peel and adhesion to a complex stent. And the coatings are much thinner than can be achieved with dip coating, saving spray material.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions