How to assemble high performance fuel cell stack?

Assemble High Performance Fuel Cell Stack – Ultrasonic Spray – Cheersonic

Any product can’t be transformed from an idea into a real object without manufacturing, and there will be errors in the manufacturing of any product. It’s impossible to produce a ruler that is absolutely equal to one meter, only a ruler that is almost one meter.

The same is true for fuel cells. There are errors in the part size and fit size of fuel cell stack. These errors will have different effects on the performance of fuel cell stack. Strict process control is needed to minimize the influence of process factors on the performance of fuel cell stack and improve the consistency of products.

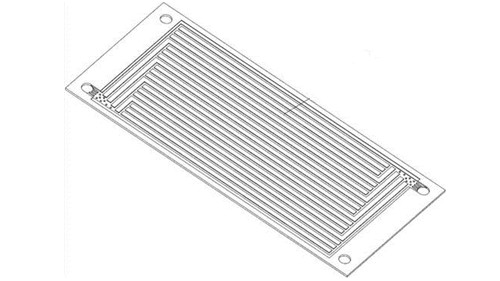

The materials of the stack include the rigid parts such as the end plate and the polar plate, and the flexible parts such as MEA and sealing line. These parts will be subjected to various forces during the assembly process and after the finished product, including the external fastening force, the elastic force of the internal diffusion layer and sealing line, and the expansion force of the membrane after absorbing water, etc.

When the end plate is fastened with bolts, there will be large deformation around the end plate and bulge in the center, resulting in uneven distribution of the compression force in the single cell near the end plate. With the increase of the number of cells, the distribution of the compression force far away from the end plate is gradually uniform. The distribution of pressing force has an important influence on the contact resistance and current density distribution of fuel cell. Therefore, strict process requirements and testing standards must be set for the deformation of end plate after assembly.

Due to the influence of stamping process, the central part of metal bipolar plate of fuel cell is often thicker than the edge, and the error accumulation of these process also has an impact on the assembly of fuel cell. A large number of tests and calculations are needed to determine the size error requirements of the plate, so that the force distribution in the active area of fuel cell is uniform.

In order to better analyze, test and control the process parameters, some professional testing equipment is necessary. In terms of stack assembly, the compression distance and compression force of stack assembly should be well controlled. Generally, the lead screw driven stacking equipment has better precision control. In addition, professional tooling equipment is needed to ensure the position error and overall shape error of each part in the assembly process of stack.

After the assembly, the shape and position tolerance of the stack can be tested by three coordinates to complete the quality control of the assembly process. For the bipolar plate and other parts with complex shape and structure and large measurement size, the rapid measurement can also be completed with the help of optical equipment.

The internal pressure of fuel cell can be measured by traditional pressure-sensitive developing paper. The pressure in different single cell and different parts of single cell can be observed by color shade to help designers improve process parameters and adjust product design. The online matrix pressure sensor can also be used for real-time compression force change test, and the dynamic compression force distribution can be seen.

With the continuous improvement of the output of fuel cell products, the quality control of products will be more and more strict. It is necessary to deeply study the influence of various process parameters on the product performance and determine the reasonable product process standard.

Ultrasonic Fuel Cell Catalyst Coating Systems

If you are interested in ultrasonic spraying system, if you want to know the price of ultrasonic spraying system, please contact us, market2@cheersonic.com