Global Trade of Hydrogen Energy

The international trade of hydrogen energy is still in its early stages, and the global hydrogen energy trade volume in 2023 is relatively small, mainly concentrated in the trade of hydrogen based products such as ammonia and methanol. These hydrogen carriers are relatively easy to store and transport, becoming an important pathway for long-distance cross-border trade of hydrogen. According to the NZE Scenario 2050, the cross regional trade volume of hydrogen and its derivatives (such as ammonia and methanol) is expected to reach 70 million tons per year by 2050, accounting for 20% of the global demand for low emission hydrogen.

Main export countries and markets:

- Main exporting countries: Australia and the United States are expected to be major hydrogen exporting countries in the future, with abundant renewable energy and natural gas resources. They plan to export hydrogen on a large scale through electrolysis of water and fossil fuel hydrogen production with CCUS. The Middle East, especially the United Arab Emirates and Saudi Arabia, is developing large-scale hydrogen export projects with the goal of becoming an important export base for low emission hydrogen globally.

- Potential import market: Europe is currently the world’s largest potential import market, with multiple countries planning to replace fossil fuel demand in industry and energy with hydrogen, particularly in industrial applications such as steel, chemical, and refining.

Infrastructure construction

Pipelines are the most cost-effective way to transport hydrogen on a large scale. By 2035, the total length of hydrogen pipelines planned globally is expected to reach 40000 kilometers, almost in line with the demand for the “2050 net zero emissions scenario”; In terms of long-distance hydrogen transportation, shipping is considered a more cost-effective option, especially in cross-border trade.

In the next few years, it is expected that over 100 new hydrogen and ammonia terminals, as well as port infrastructure, will be built globally to meet the demand for cross regional hydrogen trade. Port facilities are crucial for the global trade and supply chain stability of hydrogen.

Key regional development

Europe is actively planning a hydrogen pipeline network to achieve hydrogen interconnectivity among European countries. By 2025, Europe plans to build multiple cross-border hydrogen pipelines to support the large-scale use of hydrogen in industry and reduce dependence on fossil fuels.

Several countries in the Middle East, such as Saudi Arabia and the United Arab Emirates, are investing in the construction of hydrogen export infrastructure to produce blue and green hydrogen by utilizing abundant natural gas and renewable energy resources, and exporting them to European and Asian markets.

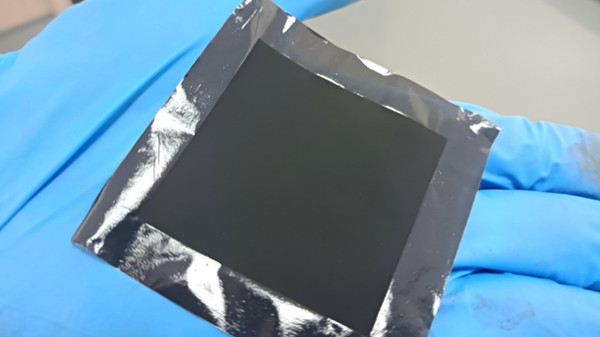

Hydrogen production by electrolysis of water is the most advantageous method for producing hydrogen. Utrasonic coating systems are ideal for spraying carbon-based catalyst inks onto electrolyte membranes used for hydrogen generation. This technology can improve the stability and conversion efficiency of the diaphragm in the electrolytic water hydrogen production device. Cheersonic has extensive expertise coating proton exchange membrane electrolyzers, creating uniform, effective coatings possible for electrolysis applications.

Cheersonic ultrasonic coating systems are used in a number of electrolysis coating applications. The high uniformity of catalyst layers and even dispersion of suspended particles results in very high efficiency electrolyzer coatings, either single or double sided.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions