ELECTROCHROMIC COATING SYSTEMS

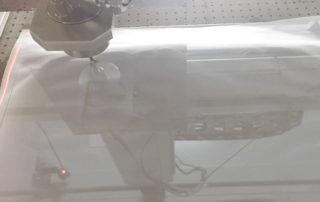

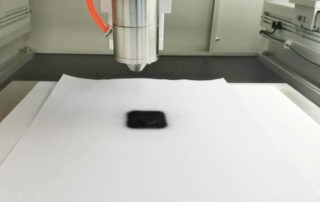

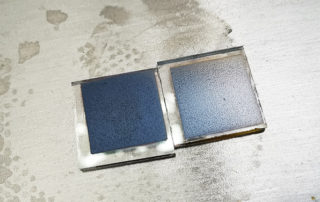

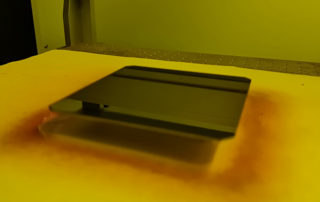

Ultrasonic spray equipment has been proven to spray ITO and other chemicals, such as nano-solutions, in the manufacture of smart or electrochromic glass. As the energy efficient glass market continues to evolve, Cheersonic assists manufacturers in developing new coating processes. The ultrasonic nozzle does not use pressure to atomize the liquid, so that the nanomaterial can be sprayed evenly onto the glass without excessive spraying or dripping. Ultrasonic spray equipment has a long life and repeatable, non-clogging performance.

ULTRASONIC COATING TECHNOLOGIES FOR ELECTROCHROMIC

- Transition metal oxides (including Tungsten oxide, Niobium oxide and other oxides)

- PMMA

- Nanocrystals

- TCO layer

- Other chemistries for glass manufacturing

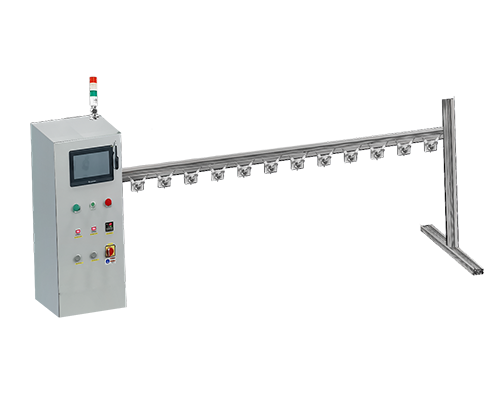

- Ultrasonic nozzles

- Nozzle corrosion resistance

- The nozzle is not easy to be blocked

- Spray range in 2-100mm diameter

- High control accuracy, spot spraying and fast startup speed

- Equipment is stable and maintenance costs are low

- Coating utilization> 95%

- Low diversion pressure and no sputtering

- Can be equipped with multiple series nozzles

- Spray special-shaped workpiece

EQUIPMENT SOLUTIONS

OUR EXPERTISES

Cheersonic offers innovative and customized solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your production.

To reach our anytime via email please fill out the form below with your request and a company representative will reply to you. To find your local CHEERSONIC representative to connect directly click your region in the contact drop down menu.

Contact CHEERSONIC For immediate assistance please contact us the corporate headquarters during business hours at 6:00 am – 22:00 pm.

Tel: 0571-87910406

- Mobile: +86 13588732518

- Email: Market2@cheersonic.com

Add: 11-13 Chuangye Road, Changkou, Fuyang, Hangzhou, Zhejiang, China