Exposure Mechanism of Positive Photoresist

Exposure Mechanism of Positive Photoresist – Photoresist Coatings – Cheersonic

Photoresist is mainly composed of photosensitive agent, resin, solvent, additives (plasticizer, surfactant, photosensitizer, etc.). Resin is the basic skeleton of photoresist and is insensitive to light. Solvents mainly include PGMEA, EGMEAD, etc., which are used to dilute photoresist and adjust its viscosity. Photosensitive agent mainly undergoes photochemical reaction to light energy.

Exposure principle of positive photoresist?

1. Step 1: Decomposition reaction of photosensitive agent The photoinitiator used in this photoresist is triphenylsulfonium chloride. Under the irradiation of ultraviolet light (hv), triphenylsulfonium chloride decomposes to generate triphenylsulfonyl cations and hexafluoroantimony anions (SbF6-), acid radical ions and free radicals.

2. Deprotection reaction of resin: The resin before exposure is a polymer containing chemical protective groups. The resin undergoes deprotection reaction under the catalytic action of acid. The protecting group (such as the Boc group, as shown below) is removed by acid catalysis to generate products soluble in the developer (such as hydroxystyrene and carbon dioxide).

Since the developer is an alkaline solution that can react with the generated acid ions, and the decomposition products of the resin are easily dissolved in water, the exposed part is more easily removed, leaving the unexposed part.

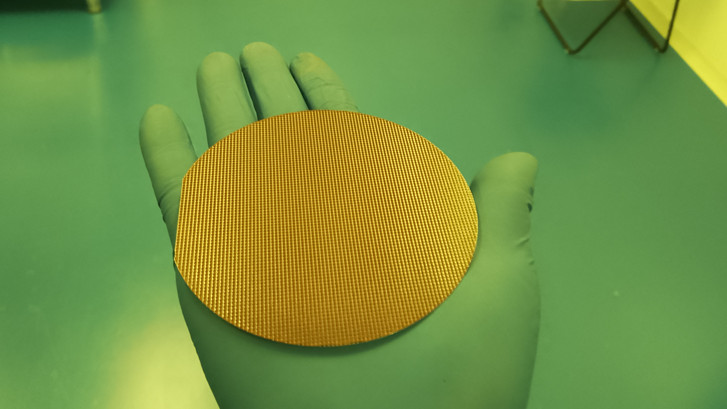

Ultrasonic spraying systems have been proven to be used in various applications that require uniform and repeatable photoresist or polyimide film coatings. The thickness control range is from submicron to more than 100 microns, and any shape or size can be coated.

Ultrasonic spraying technology is used for semiconductor photoresist coating. Compared with traditional coating processes such as spin coating and dip coating, it has the advantages of high uniformity, good encapsulation of microstructures, and controllable coating area. In the past 10 years, it has been fully demonstrated that the 3D microstructure surface photoresist coating using ultrasonic spraying technology, the prepared photoresist coating is significantly higher than the traditional spin coating in terms of microstructure wrapping and uniformity Craft.

The ultrasonic spraying system can precisely control the flow rate, coating speed and deposition volume. Low-speed spray shaping defines atomized spray as a precise and controllable pattern to avoid excessive spray when producing a very thin and uniform layer. The ultrasonic spray system can control the thickness from sub-micron to more than 100 microns, and can coat any shape or size.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions