Development of Balloon Materials

Development of Balloon Materials – Catheter Coatings – Cheersonic

So far, the vast majority of medical balloons are made of polymer materials. The original medical balloons were made of soft polyvinyl chloride (PVC). Compared with today’s balloons, this kind of balloon has a thicker wall but low pressure resistance. As scientists continue to screen and explore polymer materials, in the early to mid-1980s, balloons made of cross-linked polyethylene (PE) and polyethylene terephthalate (PET) were able to withstand pressure. And the wall thickness has been greatly improved, and to a large extent replaced PVC as a new balloon material. Balloons made of PET can withstand pressure up to 27atm, but the wall thickness can be as low as 0.0002″ to 0.002″; while balloons made of cross-linked PE can’t resist pressure compared to PET, but their shape stability is excellent. When the degree of crosslinking reaches a certain level, the change in diameter and length is less than 5% within the use pressure range.

Although PET and cross-linked PE partially solve the pressure resistance and shape retention of the balloon, their hardness is too large, and the balloon usually passes through the curved and complicated blood vessels before completing the expansion. If it cannot reach the lesion smoothly, no matter how good it is Pressure resistance and shape retention are also in vain. In the late 1980s and early 1990s, nylon and polyurethane materials began to be used in the manufacture of balloons. The strength of nylon balloons is lower than that of PET balloons, and the shape retention ability is lower than that of cross-linked PE, but they are softer. At the same time, its pressure resistance and shape retention capabilities can fully meet the requirements of medical balloons. At present, nylon occupies a large share of balloon materials.

The new balloon materials are mainly copolymers or blends of the above materials. The copolymers are mostly formed by copolymerization of rigid segments (PET, nylon) and flexible segments (olefin, ester chains). By adjusting the rigid and flexible segments The ratio is to adjust the strength and softness of the material, while the blend is a simple mixture of two compatible polymers to adjust the performance of the balloon and find a balance between strength and softness.

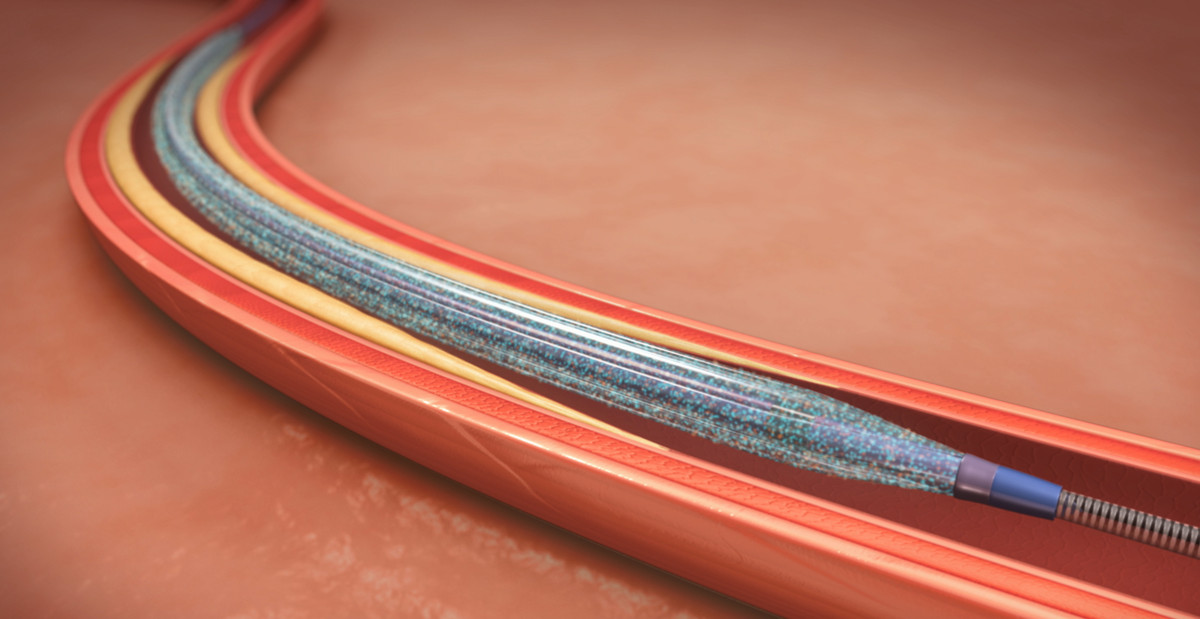

Cheersonic has extensive experience in surface coating of implantable medical devices (such as drug stents and balloons), and can provide customers with complete solutions.