Coat Nano Particle On Substrates

Coat Nano Particle On Substrates – Spraying System – Cheersonic

The latest developments in nanomaterials in different fields such as aerospace, homeland security, energy, biomedicine, and electronics all share a common standard-there is an urgent need to build tools to commercialize these research-level results and bring them to the market, and Turn its technical advantages into economic benefits. Ultrasound systems are now rapidly becoming one of the advantageous devices.

Nanomaterial user companies can bring their products to the market faster and at a lower cost. Cheersonic’s system provides an effective solution to accurately and economically distribute and deposit nanomaterials on target substrates. These include:

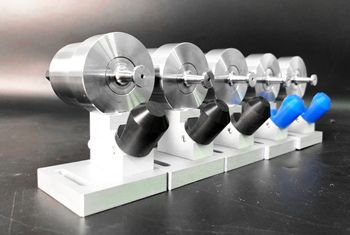

All ultrasonic spraying machines can be equipped with ultrasonic atomizing and dispersing injection pump. When conventional mixing devices and pumps are used to dispense the nanoparticles, they tend to agglomerate and separate from the liquid suspension. The ultrasonic atomizing and dispersing syringe pump transmits ultrasonic energy, which breaks down and eliminates agglomeration. The ultrasonic atomization and dispersion syringe pump makes the nanoparticles continuously suspended in a uniform mixture, thus ensuring a stable spraying process.

Cheersonic ultrasonic spraying uniformly and accurately coats a very thin layer of nanoparticles on substrates of different shapes, forms and sizes. Examples of successful commercial applications include fuel cells, solar panels, biodegradable food packaging, functional textiles, specialty glass, and biological and chemical sensors.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

The Company’s solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Cheersonic’s growth strategy is focused on leveraging its innovative technologies, proprietary know-how, unique talent and experience, and global reach to further develop thin film coating technologies that enable better outcomes for its customers’ products and processes. For further information, visit https://cheersonic-liquid.com/.