Basic Overview of the PEM Industry

Basic Overview of the PEM Industry – PEM Membrane Coating – Cheersonic

Proton exchange membranes PEMs are used in a wide range of applications. Proton exchange membranes (PEM), also known as proton membranes or hydrogen ion exchange membranes, are ion-selective permeable membranes that act as channels for proton migration and transport, separating gaseous reactants and blocking electrolytes in cells (electrolytic cells).

1. Applications

The basic structure of a proton exchange membrane fuel cell (PEMFC) consists of a membrane electrode (MEA) and bipolar plates on both sides, where the bipolar plates serve to separate the oxidising agent from the reducing agent, and the MEA is a five-in-one structure consisting of an anode/cathode gas diffusion layer (GDL), an anode/cathode catalytic layer (CL) and a proton exchange membrane (PEM). The performance of the PEM directly determines the performance and service life of the fuel cell, which is basically equivalent to the “chip” of an electronic device. The performance indicators for evaluating PEM are mainly EV (ion group equivalent value), particle conductivity, membrane thickness and cost.

2. Classification

Proton exchange membranes are classified according to their fluorine content and mainly include perfluorosulphonic acid membranes, partially fluorinated polymeric proton exchange membranes, composite proton exchange membranes and non-fluorinated polymeric proton exchange membranes. Among them, perfluorosulphate type membrane is the most commercialized PEMFC electrolyte membrane with the advantages of high mechanical strength, good chemical stability, high conductivity under high humidity conditions, high current density at low temperature and low proton conduction resistance.

3. Production process

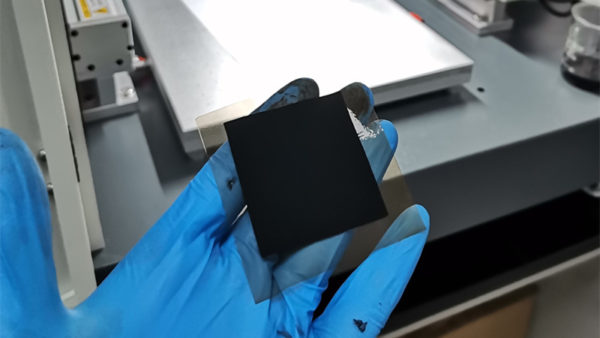

Proton exchange membrane preparation process can be divided into two categories: melt-forming method and solution-forming method, with solution-forming method being the mainstream method used for research and commercial products. The solution film formation method can be further subdivided into solution casting, solution cast and sol-gel methods according to the difference of the latter process.

Ultrasonic spray fuel cell catalyst coating system can produce highly uniform, repeatable and durable coatings. Our ultrasonic spraying can well control coating properties, significantly reduce material usage, and reduce maintenance and downtime.

Our company’s ultrasonic spraying equipment can be sprayed on a variety of different metal alloys, including the preparation of platinum, nickel, iridium and ruthenium-based fuel cell catalyst coatings, as well as PEMs, GDLs, DMFCs (direct methanol fuel cells) and SOFCs (solid Oxide fuel cell) manufacturing. The battery manufactured by this technology has the characteristics of high battery load and high battery efficiency.

The optional ultrasonic dispersion system can uniformly disperse the catalyst solution without blocking the ultrasonic nozzle, thereby providing a uniform and homogeneous fuel cell catalyst coating, and has a controlled droplet size from ultra-low flow to production-scale flow.