Application of Ultrasonic Spraying Machine in Electrolyzer Coatings

The application of ultrasonic spraying machines in electrolyzer coatings is mainly reflected in the following aspects:

1. Technical principles and advantages

Ultrasonic spraying technology uses tiny droplets generated by high-frequency vibration to effectively break the surface tension of the liquid through ultrasonic vibration to form uniform, fine droplets. This technology has several significant advantages:

- High spraying efficiency: Ultrasonic spraying technology can complete large-area spraying in a short time, significantly improving production efficiency.

- Good spraying effect: By controlling the frequency and power of ultrasonic waves, precise control of the size and distribution of spray droplets can be achieved, thereby obtaining better spraying effects.

- Improve catalyst utilization: Ultrasonic spraying technology can spray catalyst more uniformly on the electrode surface, thereby increasing catalyst utilization, reducing catalyst costs, and improving electrolytic cell performance.

- Green and environmentally friendly: Ultrasonic spraying technology does not require the use of organic solvents or other chemicals, so it has environmental advantages and helps reduce exhaust emissions during the spraying process.

- Suitable for a variety of catalysts: This technology is suitable for many types of catalysts, including noble metal catalysts and non-precious metal catalysts.

2. Specific application in electrolytic cell spraying

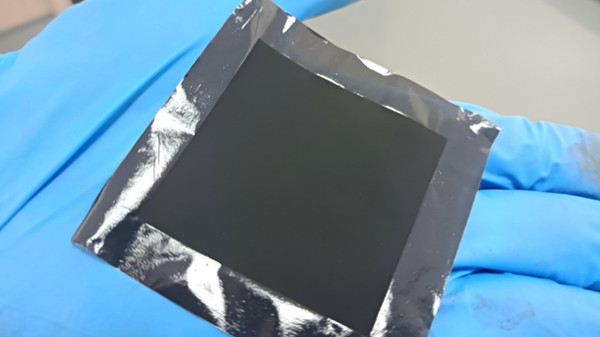

- PEM electrolyzer spraying

Application background: PEM (proton exchange membrane) electrolyzer is a device that splits water into hydrogen and oxygen. It is widely used in fuel cells, hydrogen production and storage and other fields. In order to improve the performance and efficiency of PEM electrolyzers, catalyst spraying is one of the key steps.

Application examples: Ultrasonic spraying technology is widely used in catalyst spraying of PEM electrolyzers. Through ultrasonic spraying, the catalyst can be more evenly distributed on the electrode surface, thereby improving the electrolysis efficiency and stability of the electrolytic cell. In addition, the technology is suitable for double-sided coating and allows different catalyst formulations to be applied to each side of the membrane, further increasing the flexibility and performance of the electrolyzer. - Other types of electrolytic cell spraying

In addition to PEM electrolytic cells, ultrasonic spraying technology is also suitable for other types of electrolytic cell spraying. For example, in the preparation process of AEM (anion exchange membrane) electrolyzers, ultrasonic spray technology can also play an important role. By precisely controlling the spraying parameters, it is possible to ensure that the coating material forms a uniform and dense coating on the electrode surface, thereby improving the corrosion resistance and conductive performance of the electrolytic cell.

3. System composition and work flow

Ultrasonic spraying systems usually consist of ultrasonic atomizing nozzles, dedicated drive power supplies, XYZ three-axis linkage servo systems, intelligent operating systems, liquid supply systems, and low-speed air shaping devices. During the working process, high-frequency sound waves are converted into mechanical energy through the piezoelectric transducer, which then drives the liquid to form tiny droplets. These droplets are further refined under the action of ultrasonic nozzles and evenly sprayed on the electrode surface of the electrolytic cell.

4. Summary and Outlook

The application of ultrasonic spraying machine in electrolytic tank spraying shows its unique advantages and broad application prospects. With the continuous advancement of technology and reduction of costs, ultrasonic spray technology is expected to play a greater role in the field of electrolytic cell preparation and promote the rapid development of the hydrogen energy industry. In the future, with the continuous improvement of electrolytic cell performance requirements and the increasing awareness of environmental protection, ultrasonic spray technology will become one of the important technologies in the field of electrolytic cell preparation.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions