Advantages of Ultrasonic Spraying Quantum Dot Solution

Ultrasonic spraying of quantum dot solution, as an advanced spraying technology, has a series of significant advantages, but also some potential disadvantages. The following is a detailed analysis of its advantages and disadvantages:

Advantage

- High uniformity of coating:

Ultrasonic spraying technology uses ultrasonic vibration to atomize quantum dot solution into fine particles, which can be evenly distributed on the surface of the substrate during the spraying process, forming a highly uniform coating. This high uniformity helps to improve the appearance quality and performance stability of the product. - Accurate control of coating thickness:

By adjusting the frequency, amplitude, and spraying parameters of ultrasonic waves, the thickness of the coating can be precisely controlled. This is particularly important for application scenarios that require strict control of coating thickness, such as the preparation of nanoscale thin films. - High utilization rate of raw materials:

During the ultrasonic spraying process, the atomization of the coating does not require high-pressure gas, reducing liquid rebound and splashing, thereby greatly improving the utilization rate of the coating. Compared to traditional spraying methods, ultrasonic spraying can significantly reduce material waste and lower production costs. - Strong adaptability:

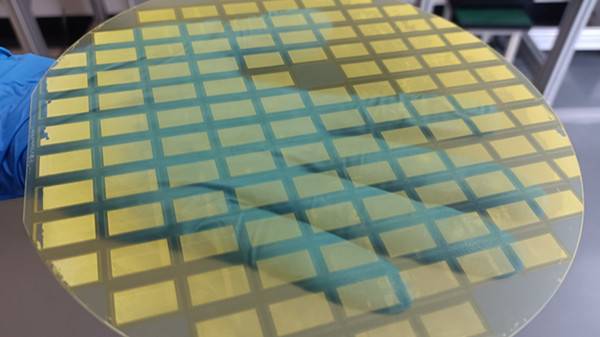

Ultrasonic spraying technology is applicable to various types of quantum dot solutions, including solutions with different compositions, viscosities, and concentrations. At the same time, it is also applicable to various substrates such as glass, silicon wafers, metals, etc., with wide applicability. - Environmentally friendly and pollution-free:

During the ultrasonic spraying process, no harmful gases or waste are generated, and there is no pollution to the environment. In addition, this technology can also reduce the amount of solvent used, further reducing its impact on the environment.

Ultrasonic spray quantum dot solution has the advantages of high coating uniformity, precise coating thickness control, high raw material utilization, strong adaptability, and environmental friendliness without pollution. However, it also has the disadvantage of high requirements for substrates and coatings. In practical applications, it is necessary to choose appropriate spraying methods and equipment based on specific needs and conditions.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions