Advantages of Ultrasonic Spraying Pharmaceutical Solution

The advantages of ultrasonic spraying pharmaceutical solution are as follows:

1. Good spraying effect:

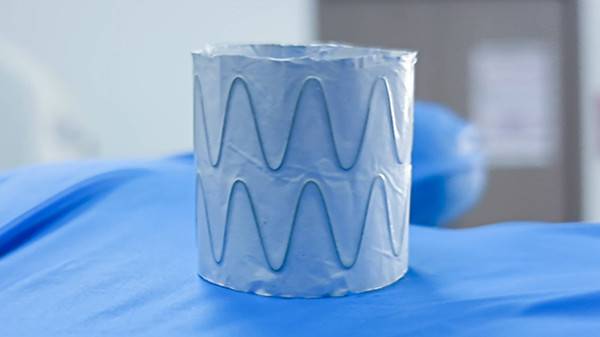

- High uniformity: Ultrasonic spraying can evenly atomize the pharmaceutical solution into tiny particles. These particles are uniform in size and distributed very evenly, so that the liquid can be evenly covered on the target surface. For example, spraying drug coatings on the surface of some medical devices. Uniform spraying can ensure that the dose and effect of the drug are more stable, helping to improve the therapeutic effect.

- Controllable coating thickness: By accurately controlling parameters such as the frequency, power, and spraying time of ultrasonic waves, the thickness of the coating formed by the chemical solution on the target surface can be precisely controlled. This precise control capability is very important for some applications that have strict requirements on drug dosage, such as drug sustained-release coatings.

2. High material utilization rate:

Ultrasonic spraying does not require the use of high-pressure gas in the process of atomizing liquid medicine, so the splashing and waste of liquid medicine are greatly reduced. Compared with traditional spraying methods, ultrasonic spraying can increase the utilization rate of pharmaceutical liquids several times, especially for some expensive drugs, which can significantly reduce production costs.

3. Wide scope of application:

A variety of liquids can be sprayed: whether it is a water-based liquid, an oily liquid or a suspension containing solid particles, ultrasonic spraying can handle it well. For example, in the pharmaceutical industry, different types of pharmaceutical preparations can be accurately sprayed using ultrasonic spray technology.

Suitable for a variety of substrates: For substrates of different materials, such as metal, plastic, glass, ceramics, etc., ultrasonic spraying can achieve good liquid adhesion, so it is used in many fields such as medical devices, electronic equipment, and packaging materials. Has a wide range of applications.

4. Little impact on the properties of the medicinal solution:

During the ultrasonic spraying process, the mechanical stress on the liquid medicine is relatively small, and it does not produce high-pressure and high-speed shear forces like some traditional spraying methods, so that the original properties of the liquid medicine, such as the activity of the drug, can be maintained to the greatest extent. , stability, etc. This is a very important advantage for some drugs that are sensitive to conditions such as temperature and pressure.

5. Clean and environmentally friendly:

Due to the high utilization rate of the chemical liquid, less waste and pollutants are generated during the spraying process, and the pollution to the environment is relatively small. At the same time, ultrasonic spraying equipment is easy to clean and does not easily retain liquid chemicals like traditional spraying equipment, reducing pollution to the production environment and health hazards to operators.

6. Easy to operate:

The operation of ultrasonic spraying equipment is relatively simple and easy to realize automatic control. Through preset parameters, continuous and stable spraying operations can be achieved, improving production efficiency and product quality stability.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions