A Complete Analysis of Biomass Hydrogen Production Technology

In the field of energy, biomass, as an organic substance directly or indirectly generated by photosynthesis, covers plants, animals, microorganisms and their excrement and metabolites, and plays an important role. The biomass energy contained in biomass converts and stores solar energy through photosynthesis of organisms. It has become an important source of energy due to its renewable and extensive resource characteristics. Taking my country as an example, the amount of crop straw that can be used for energy reaches 280 million to 350 million tons each year. It is worth mentioning that although biomass produces carbon monoxide when used, its carbon dioxide emissions come from the atmosphere and will not increase additional carbon emissions.

As a key way to utilize biomass energy, biomass hydrogen production is mainly divided into two major technical camps: thermochemical hydrogen production and biological hydrogen production.

Thermochemical hydrogen production

Thermochemical hydrogen production includes a variety of technical means, such as biomass catalytic gasification hydrogen production, biomass pyrolysis hydrogen production, and bio-oil reforming hydrogen production. Converting biomass into methanol and ethanol, and then generating hydrogen through steam reforming, is a relatively mature technical route at present.

- Biomass catalytic gasification to produce hydrogen: This technology is to place biomass in a medium such as air, oxygen or water vapor, heat it to 800-900℃, and cause it to decompose to produce hydrogen, carbon monoxide and other gases. The key technology is to increase hydrogen production while reducing the generation of impurities such as tar. Trace impurities such as H₂S, HCl, alkali metals, heavy metals, etc. generated in the process need to be treated with adsorbents.

- Biomass pyrolysis to produce hydrogen: In an oxygen-deficient or low-oxygen environment, heat energy is used to break biomass macromolecular hydrocarbons to produce tar, carbon monoxide, hydrogen, etc. Secondary catalytic cracking of the generated tar can also further obtain hydrogen.

- Bio-oil reforming to produce hydrogen: Proposed by the National Renewable Energy Laboratory (NREL) of the United States, biomass is first pyrolyzed to obtain bio-oil, and then steam reforming is performed to produce hydrogen.

- Hydrogen production from methanol and ethanol: Given that the technology of producing methanol and ethanol from biomass is relatively mature, subsequent hydrogen production through methanol and ethanol steam reforming has also become a feasible path.

Although the thermochemical method has certain feasibility at the technical level, and even commercial devices have been put into operation, there are still problems. Compared with traditional methane reforming technology, the cost of hydrogen production from biomass is relatively high and the economic competitiveness is insufficient. In addition, the product has a low hydrogen content and more impurities. These impurities will damage fuel cells and limit its application in scenarios where high-purity hydrogen is required.

Biological hydrogen production

Biological hydrogen production mainly covers three technical routes: dark anaerobic fermentation hydrogen production, photosynthetic biological hydrogen production, and photosynthetic-fermentation composite biological hydrogen production.

- Dark anaerobic fermentation hydrogen production: Anaerobic microorganisms use nitrogenase or hydrogenase to degrade organic matter to generate hydrogen. This process does not rely on light energy. The microorganisms involved in this process include obligate anaerobes, facultative anaerobes, and a few aerobic bacteria.

- Photosynthetic biohydrogen production: including photolysis of water to produce hydrogen and photofermentation of hydrogen. Photolysis of water to produce hydrogen relies on photosynthetic microorganisms such as cyanobacteria and green algae to decompose water to produce hydrogen; photofermentation of hydrogen uses bioenergy and light energy to promote hydrogen production under anaerobic light conditions.

- Photosynthesis-fermentation composite biohydrogen production: It combines the advantages of dark fermentation and photofermentation, which can not only reduce the demand for light energy, but also increase hydrogen production, and is expected to become the development direction of biomass hydrogen production in the future.

At present, dark fermentation hydrogen production has entered the pilot stage, but it needs to further improve efficiency and reduce costs before it can be industrialized. Photofermentation and composite biohydrogen production technology are still in the laboratory research stage.

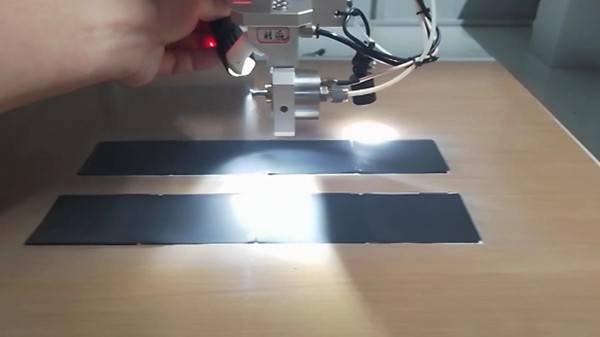

Ultrasonic spraying equipment is used in many electrolytic coating applications. The high uniformity of the catalyst layer and the uniform dispersion of suspended particles can create very efficient electrolyzer coatings, whether single-sided or double-sided. In green hydrogen production, hydrogen is produced by electrolysis of water, producing only hydrogen and oxygen. Ultrasonic spraying equipment coats the electrolyzer in this truly green energy production process.

Ultrasonic spraying equipment has proven to be ideal for coating PEM electrolyzers in high-volume hydrogen fuel cell production, and is ideal for spraying carbon-based catalyst inks onto electrolyte membranes. Ultrasonic spraying equipment is fully automated, capable of double-sided coating, and able to apply different catalyst formulations to each side of the membrane. The durability and repeatability of the coatings have been shown to be superior to other coating methods, often providing not only longer life of the coated PEM, but also higher efficiency.

In carbon capture electrolysis applications, ultrasonic coating equipment applies catalysts to membranes used to separate and capture carbon dioxide before it enters the atmosphere. Carbon dioxide is separated from other gases in exhaust streams produced by industrial processes, such as those from coal and natural gas power plants or steel and cement plants; with the goal of reducing carbon emissions to combat global warming. Typically, the captured carbon dioxide can be processed into valuable carbon-based byproducts such as plastics, rubber or fuels.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions