Introduction to Drug Eluting Stents

Introduction to Drug Eluting Stents – Stent Coated – Cheersonic

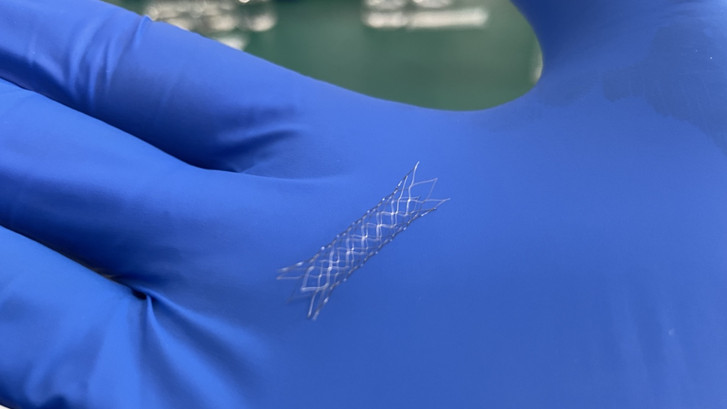

In response to the high restenosis rate of bare metal stents, scientists have come up with another idea, which is to coat the surface of the stent with a drug that inhibits cell proliferation, so that the drug can be released slowly, effectively inhibiting the proliferation of vascular smooth muscle cells, thereby reducing the occurrence of vascular restenosis. .

First-generation drug-eluting stents

The first-generation drug-eluting stents are represented by Sirolimus-coated Cypher stents and paclitaxel-coated Taxus stents, both of which use stainless steel skeletons as platforms, with relatively thick stent walls and non-degradable polymer coating materials. However, the global craze for first-generation drug-eluting stents was quickly extinguished, as multiple clinical studies showed that although it can significantly reduce the incidence of restenosis, it may increase the risk of late stent thrombosis. Because stent thrombosis is often fatal, scientists have begun to develop a new generation of drug-eluting stents.

Second-generation drug-eluting stents

Drug-eluting stents are mainly composed of stent skeleton, polymer coating and anti-proliferative drugs. The second-generation drug-eluting stents have been improved in these three aspects. First, the stent skeleton was replaced by a stainless steel material with a higher strength cobalt-chromium alloy or platinum-chromium alloy, which made the thickness of the stent wall thinner; on the polymer coating, phosphorylcholine, vinylidene fluoride and other biocompatible materials were selected. Good polymers can reduce local inflammatory reactions or allergic reactions; anti-proliferative drugs are replaced by everolimus, zotarolimus and other less cytotoxic derivatives of sirolimus to reduce local inflammatory effects. Through the continuous improvement of stent materials and technologies, the rate of restenosis after stenting and the incidence of stent thrombosis have been continuously reduced.

Biodegradable Polymer Drug Eluting Stents

Biodegradable polymer drug-eluting stents have become a research hotspot in recent years. Although second-generation drug-eluting stents significantly reduce the incidence of stent thrombosis, the permanent polymer coating contained is highly sensitizing, and can cause chronic vascular inflammation and increase the risk of in-stent restenosis. Scientists once again focused on the coating, hoping to reduce the inflammatory response caused by the polymer and speed up the endothelial repair by using a fully degradable polymer coating, so the biodegradable polymer drug-eluting stent came into being. . However, so far, several studies have shown that biodegradable polymer drug-eluting stents do not bring additional clinical benefits compared with second-generation drug-eluting stents.

The process of continuous innovation of stents is a process of human struggle against diseases, and the invention of each new type of stents all condensed the great efforts of scientific researchers and clinicians. Medicine is endless. With the development of technology, it is believed that drug-eluting stents will be updated in the future. But it is worth mentioning that stent implantation is not the end point of coronary heart disease treatment. It is necessary to rationally use adenosine and other drugs to avoid complications such as no-reflow during stent implantation. , Regular use of drugs to improve microcirculation, antiplatelet drugs, statins, β-blockers.

Cheersonic ultrasonic coating systems have been used to spray anti-restenosis drug eluting polymer solutions onto implantable stents for decades. We have expertise in spraying hundreds of different medical grade polymer chemistries. Ultrasonic spray nozzles are advantageous in penetrating complex stent geometries, ensuring full coverage of all strut surfaces without webbing. The soft atomized spray adheres well to surfaces and coating morphology characteristics can be adjusted by modifying process parameters.