What is a photolithography machine used for?

What is a photolithography machine used for? Catalyst Coated Membranes – Cheersonic

Mask Aligner, also known as mask alignment exposure machine, is the core equipment of the lithography process in the chip manufacturing process. The manufacturing process of a chip is extremely complex, but it can be summed up in several major steps:

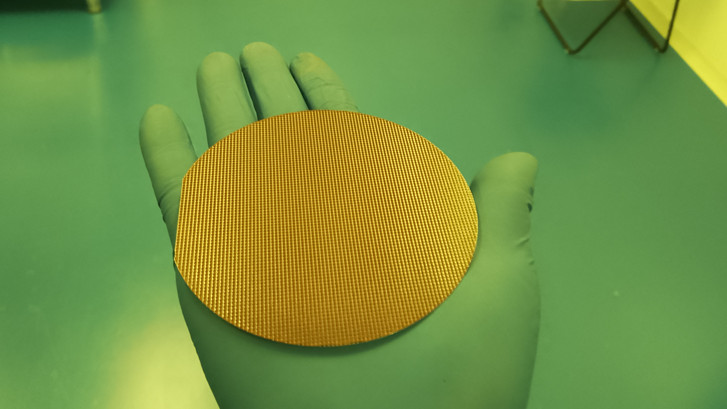

Preparation of silicon wafers–>Epitaxy process–>thermal oxidation–>diffusion doping–>ion implantation–>film preparation–>lithography–>etching–>process integration, etc.

The lithography process is the most critical step in the manufacturing process. Lithography determines the key dimensions of the chip and accounts for about 35% of the overall manufacturing cost in the entire chip manufacturing process. The photolithography process transfers the geometry on the mask (lithography) to the photoresist on the wafer surface. First, the photoresist processing equipment spins the photoresist onto the surface of the wafer, and after repeated exposure and development processing step by step, the desired pattern is formed on the wafer.

The difficulty of this process is usually expressed by the number of masks that a process needs to pass through. According to different exposure methods, lithography can be divided into contact type, proximity type and projection type; according to the number of facets, there are single-sided alignment lithography and double-sided alignment lithography; Thin-resist lithography and thick-resist lithography. The lithography machine itself can be divided into several categories according to the application, the lithography machine used for manufacturing chips, the lithography machine used for packaging and the projection lithography machine used in the field of LED manufacturing.

Lithography machines are generally divided into three types according to the ease of operation, manual, semi-automatic, and fully automatic.

Manual: refers to the adjustment method of alignment, which is accomplished by changing its X axis, Y axis and thita angle through the manual adjustment knob, and the alignment accuracy can be imagined not high;

Semi-automatic: It means that the alignment can be adjusted by the electric axis according to the CCD;

Automatic: It refers to uploading and downloading from the substrate. The exposure time and cycle are controlled by the program. The automatic lithography machine mainly meets the needs of the factory for processing capacity.

The general lithography process includes bottom film processing, gluing, pre-baking, alignment exposure, development, etching, de-adhesive lithography inspection, etc. The operations in the process can be adjusted according to the actual situation.

Ultrasonic spraying technology is used for semiconductor photoresist coating. Compared with traditional coating processes such as spin coating and dip coating, it has the advantages of high uniformity, good encapsulation of microstructures, and controllable coating area. In the past 10 years, it has been fully demonstrated that the 3D microstructure surface photoresist coating using ultrasonic spraying technology, the prepared photoresist coating is significantly higher than the traditional spin coating in terms of microstructure wrapping and uniformity Craft.