Cartilage Defect Repair Hydrogel Material

Cartilage Defect Repair Hydrogel Material – Ultrasonic Cutter – Cheersonic

Cartilage defect is a common clinical disease, which can lead to osteoarthritis in the advanced stage. Severe cartilage damage can involve the subchondral bone, resulting in a full-thickness defect of the cartilage and subchondral bone. Due to the different structures and functions of cartilage and subchondral bone, the integrated repair of osteochondral defects faces many difficulties. As an ideal tissue engineering material, injectable hydrogel can provide a microenvironment close to the natural extracellular matrix for cell proliferation and differentiation. A hydrogel material suitable for the repair of osteochondral defects with mechanical properties and functionality.

1. Hydrogel for cartilage defect regeneration based on alginate-dopamine/chondroitin sulfate/silk fibroin/exosomes

Basic information of hydrogel materials:

1) Composition: alginate-dopamine (AD), chondroitin sulfate (CS), regenerated silk fibroin (RSF), mesenchymal stem cell-derived exosomes (EXO).

2) Features: wet environment adhesion, excellent biocompatibility, slow release of exosomes.

3) Function: cartilage defect regeneration.

2. Antitumor and bone defect-promoting hydrogels based on upconverted nanoparticles and alginate

Basic information of hydrogel materials:

1) Composition: UCNP-AuNP, sodium alginate.

2) Features: injectable, in situ enhanced, photothermal response.

3) Function: cartilage defect regeneration and fracture repair.

Hemostatic sponge is a dense, porous, positively charged hemostatic material. When it comes into contact with human blood, it can immediately adhere and aggregate platelets, thereby causing blood to form thrombus, block wounds, and release various coagulation-related substances. Factors, under the combined action of endogenous and exogenous coagulation pathways, make blood form stable fibrin polymers, thereby forming blood clots and achieving the purpose of wound hemostasis.

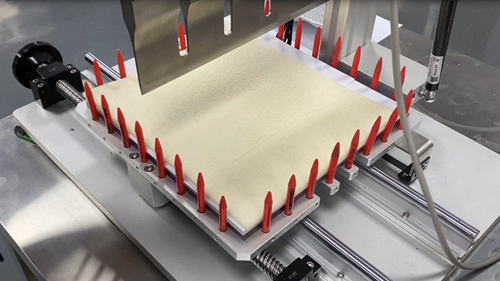

Because of its special function and special material, the hemostatic sponge has the characteristics of high elasticity, strong toughness, and long exposure time, so it is difficult to be processed by traditional mechanical cutting. Ultrasonic cutting avoids the shortcomings of traditional mechanical cutting to a certain extent, and can cut the hemostatic sponge at various angles and directions, and the hemostatic sponge is still smooth and smooth after cutting.

Ultrasonic vibration reduces the frictional resistance between the blade and the hemostatic sponge, so that the blade can cut the hemostatic sponge smoothly without deformation, and there will be no burnt cut surface. Ultrasonic vibration reduces material sticking on the blade, thereby reducing downtime in cleaner production systems. Throughout the cutting process, the blade surface remains smooth, clear and clean.