Lithium-ion Energy Storage Battery and Power Battery

Differences between lithium-ion energy storage batteries and power batteries

In today’s energy field, lithium-ion batteries occupy an extremely important position. In the lithium-ion battery family, energy storage batteries and power batteries are two key branches. Due to the particularity of energy storage batteries themselves, they are significantly different from power batteries in multiple dimensions. A deep understanding of these differences will not only help us better understand the nature of these two batteries, but also provide strong support for the development of related industries. At the same time, the application of ultrasonic spraying technology in the battery field has also brought new opportunities for improving battery performance.

Application scenarios: each with its own focus

Energy storage battery

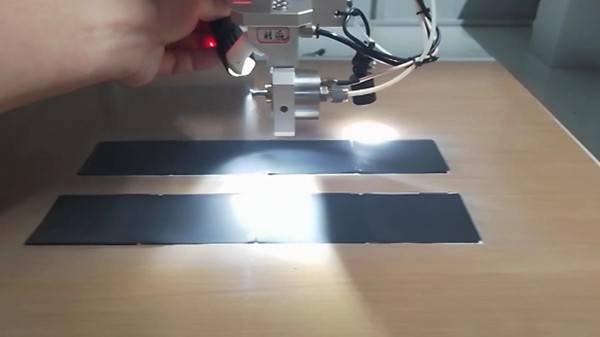

Small household energy storage provides a new model for household electricity use. It can store electricity during low electricity consumption and release it during peak hours, helping families to use energy reasonably and reduce electricity costs. Large base station energy storage plays a vital role in the power system. In terms of peak shaving and valley filling, by charging during low electricity consumption and discharging during peak hours, it can not only balance the load of the power grid, but also earn electricity price differences for operators. In power grid frequency modulation, energy storage batteries can quickly respond to changes in grid frequency, adjust power output, and ensure the stable operation of the power grid. In the rectification link of wind power and photovoltaic power, energy storage batteries can store unstable new energy electricity, so that it can be more stably integrated into the power grid. Ultrasonic spraying technology can be used for the preparation of electrode coatings in the production of energy storage batteries. By precisely controlling the thickness and uniformity of the coating, the energy storage efficiency of the battery can be improved, and the demand for long cycle life and efficient energy storage of energy storage batteries in different application scenarios can be better met.

Power battery

Power batteries are designed for mobile devices such as electric vehicles, electric bicycles, and power tools. The space and weight restrictions of automobiles require that power batteries must provide sufficient energy within a limited volume and weight. The instantaneous high power demand during startup and acceleration, coupled with the consideration of vehicle endurance and performance by the national subsidy policy, makes power batteries face stringent requirements in terms of energy density, volume density, charge and discharge rate, and battery safety. This also leads to its relatively high cost. When preparing power battery electrodes, ultrasonic spraying can make the active materials more evenly distributed on the electrodes, improve the conductivity and stability of the electrodes, and help meet the requirements of high energy density and high power output of power batteries, thereby improving the endurance and acceleration performance of electric vehicles.

Charging and discharging characteristics: completely different requirements

Energy storage battery

Generally speaking, the charging and discharging rate of energy storage batteries is low, and the requirements for charging and discharging speed are not urgent. It focuses more on long-term cycle life and energy storage efficiency. However, in some special scenarios, such as energy storage batteries used in grid frequency modulation, high-rate charging and discharging performance is required to quickly respond to changes in grid frequency. The battery electrode coating prepared by ultrasonic spraying technology has better structural stability and can adapt to the different charging and discharging requirements of energy storage batteries. Whether it is conventional low-rate charging and discharging or high-rate requirements in special scenarios, it helps to extend the cycle life of the battery and ensure the efficiency of energy storage and release.

Power battery

In order to meet the high-power output requirements when the vehicle accelerates and climbs, the power battery must have the ability to support high-rate charging and discharging. The dynamic changes of the vehicle during driving require the power battery to quickly provide a large amount of electrical energy, which poses a great challenge to its charging and discharging characteristics. Ultrasonic spraying improves the microstructure of the electrode and enhances the ion transmission efficiency, so that the power battery can work more stably during high-rate charging and discharging, reduce battery heating and performance degradation, and ensure the power performance of the vehicle.

Energy density and power density: different considerations

Power battery

For passenger cars, just as gasoline is expected to have high energy density, automotive lithium-ion batteries also need high energy density and high power output. Only in this way can more energy be carried in a limited space to meet the requirements of electric vehicles for cruising range and acceleration performance. Smaller volume and weight can achieve long cruising range and strong power, which has always been the goal of power batteries. Ultrasonic spraying makes the active material adhere more firmly and distribute more evenly on the electrode, increases the active area of the electrode, and thus helps to improve the energy density and power density of the power battery, providing support for longer cruising range and stronger power.

Energy storage battery

In peak shaving and valley filling applications, energy storage batteries are generally charged and discharged twice a day, and usually have a large storage space. Therefore, it has no special requirements for the energy density and power density of the battery cell, but pays more attention to safety and cost. Energy storage batteries often use stable electrochemical materials and loose battery structures to ensure long-term stable operation. Ultrasonic spraying technology also plays a role in ensuring the safety of energy storage batteries. By optimizing the electrode coating, it reduces safety hazards such as internal short circuits in the battery. At the same time, without affecting the performance, it reduces the material waste in the production process to a certain extent, which helps to control costs.

Cycle life: the test of time

Energy storage battery

Energy storage equipment is a long-term investment project, and the owner unit usually expects it to have a long working life and cycle life. Taking the peak-shaving battery as an example, the general payback period is 4-6 years, and accordingly, its life requirement may be as long as 8 years or more. Long cycle life can ensure that the energy storage battery continues to play a role stably during many years of use, reducing the overall investment cost. The electrode coating prepared by ultrasonic spraying has good durability, can maintain stable performance in long-term charge and discharge cycles, effectively extend the cycle life of the energy storage battery, and meet the owner unit’s demand for long-term use.

Power battery

The general life requirement of a power battery is 5 years or 300,000 kilometers, and the number of cycles is about 1,000-2,000 times. This is set according to the normal service life and mileage of the vehicle. During this life cycle, the power battery must always maintain a certain performance level to ensure the normal operation of the vehicle. Ultrasonic spraying technology helps to improve the stability of the power battery electrode. After multiple charge and discharge cycles, it can still maintain good battery performance, so that the power battery can better meet the specified life requirements.

Cost: Different algorithms for economic accounts

Energy storage battery

Given the differences in application scenarios and performance requirements, cost control has become a key factor in the large-scale application of energy storage batteries. Only by reducing costs can the economy of large-scale energy storage systems be achieved, allowing energy storage batteries to be more widely used in the field of energy storage. Ultrasonic spraying technology contributes to the cost control of energy storage batteries from multiple aspects by accurately controlling the amount of coating materials, reducing material waste, and improving production efficiency, helping to achieve the economic feasibility of large-scale energy storage systems.

Power battery

While ensuring performance, power batteries are also constantly working to reduce costs. However, due to its strict requirements for high performance, the cost is relatively high. However, with the continuous advancement of technology, including the optimization of production processes, such as the application of ultrasonic spraying technology, while improving performance, it is also gradually driving down costs to promote the further development of industries such as electric vehicles.

Safety: Protection of life and property

Power battery

Since the power battery is installed on the vehicle and faces various complex application scenarios, especially in the event of a traffic accident, it must be ensured that the battery will not catch fire or explode to protect the life safety of the driver and passengers. This places extremely high demands on the safety design of power batteries. Ultrasonic spraying technology optimizes the structure and performance of the electrode during the preparation of the battery electrode, reduces the risk of safety accidents caused by internal short circuits in the battery, and provides technical support for improving the safety performance of power batteries.

Energy storage battery

The energy storage battery system is large in scale, and once a fire occurs, it may cause serious consequences. Therefore, the fire protection standards for energy storage batteries are usually more stringent, covering multiple aspects such as the response time of the fire extinguishing system, the amount and type of fire extinguishing agent, etc. Although the energy storage battery is in a non-moving state, there is no need to consider vibration, ball hitting, etc. when designing the product, but the safety of the internal structure and materials of the battery cannot be relaxed. Ultrasonic spraying technology enhances the stability of the battery by improving the quality of the battery electrode coating, which helps to reduce the possibility of safety accidents such as fire caused by internal battery failure.

Material selection: performance-oriented choice

Power battery

As mentioned above, the demand for high energy density in power batteries is extremely urgent. To meet this requirement, in the production process, positive electrode materials with higher specific capacity are usually selected, such as high-nickel ternary materials and lithium iron phosphate. Graphite is generally selected as the negative electrode material. At present, the power battery technology of passenger cars is constantly innovating, and the concept of solid-state batteries has emerged, that is, solid electrolytes or lithium metals are used as negative electrodes. In the application of power battery materials, ultrasonic spraying technology can better combine different materials and give full play to the best performance of materials. For example, in the preparation of electrodes of high-nickel ternary materials, the stability and conductivity of the materials can be improved by precisely controlling the coating, and the high energy density potential of the materials can be further explored.

Energy storage battery

Energy storage batteries pay more attention to long cycle life and cost-effectiveness. Therefore, in the selection of positive electrode materials, lithium iron phosphate, lithium manganese oxide, etc. may be preferred. In terms of electrolytes, energy storage batteries have relatively low requirements for ion conductivity, but high requirements for stability and cost. Ultrasonic spraying technology can optimize the structure of the electrode coating of energy storage batteries, so that the selected materials can better adapt to the performance requirements of energy storage batteries, while ensuring long cycle life, reducing costs and improving the overall performance of batteries.

There are many differences between lithium-ion energy storage batteries and power batteries in terms of application scenarios, charging and discharging characteristics, energy density and power density, cycle life, cost, safety, and material selection. Ultrasonic spraying technology, with its advantages in the preparation of battery electrode coatings, can improve battery performance from multiple angles based on the different characteristics of the two batteries, inject new vitality into the development of the battery industry, and play an important role in promoting the progress of related industries such as energy storage and electric vehicles.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions