Advantages of Dry Electrodes

Advantages of Dry Electrodes – High Volume Electrolyzer Coatings – Cheersonic

The dry electrode process reduces overall capital and operating expenses. In addition, the dry electrode process has a higher production yield, which also reduces costs and energy consumption.

The residual solvent in the electrode will also react with the electrolyte to reduce the electrode performance, such as reduced capacity, gas generation and shortened life, while the dry electrode is solvent-free, avoiding these problems.

During the solvent evaporation process of the wet electrode, the binder and conductive agent will float and concentrate near the surface with the solvent, while the active material will precipitate, resulting in electrode stratification, which will damage the construction of the 3D conductive network in the electrode and reduce the bonding strength between the active material and the current collector. The dry electrode is solvent-free, which can avoid this problem.

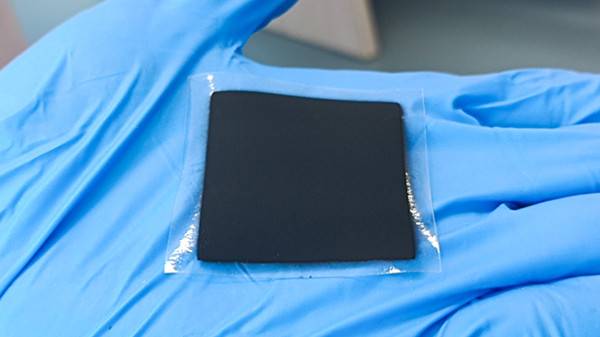

During the solvent evaporation process of the wet coating, the electrode is prone to cracks, especially the thick electrode, and the electrode thickness is limited by the wet coating manufacturing process. The dry electrode process can prepare ultra-thick electrodes.

No solvent is used in the production process of dry electrodes. The binder exists in a fibrous state and only has point contact with the surface of the active material particles, which does not affect the internal contact between the active material particles. The contact between the active material particles and the conductive agent particles is closer, and the conductivity of the electrode is good. Moreover, Li+ can be better embedded and released on the surface of the active material, with high capacity, which is beneficial for high-rate discharge.

Compared with traditional slurry coatings, dry electrode coatings can achieve higher bonding strength. Films based on dry processes can achieve low binder content (<1wt%) while ensuring bonding strength. Test results show that the peel strength of dry electrode sheets is 3.2 times that of wet processes.

Hydrogen production by electrolysis of water is the most advantageous method for producing hydrogen. Utrasonic coating systems are ideal for spraying carbon-based catalyst inks onto electrolyte membranes used for hydrogen generation. This technology can improve the stability and conversion efficiency of the diaphragm in the electrolytic water hydrogen production device. Cheersonic has extensive expertise coating proton exchange membrane electrolyzers, creating uniform, effective coatings possible for electrolysis applications.

Cheersonic ultrasonic coating systems are used in a number of electrolysis coating applications. The high uniformity of catalyst layers and even dispersion of suspended particles results in very high efficiency electrolyzer coatings, either single or double sided.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions