AEM Hydrogen Production Advantages

AEM Hydrogen Production Advantages – Electrolyzer Coatings – Cheersonic

AEM-WE has the potential to operate at significantly reduced costs, without the need for precious metals and fluoropolymer membranes in components, and with simpler operating conditions, opening up new avenues for large-scale and sustainable production of green H2. Specifically, it can be divided into the following three aspects:

Although PEM-WE hydrogen production technology has high efficiency, its performance depends largely on the electrocatalysts of rare elements, such as iridium (Ir) for oxygen evolution reaction (OER) and iridium (Ir) for hydrogen evolution reaction (HER). ) of platinum (Pt). Not only are these catalysts rare earth elements, but their main production areas are concentrated in South Africa and Russia, which makes their supply geographically concentrated. Additionally, the costs of these catalysts fluctuate unpredictably, further increasing the risk of their use.

In contrast, AEM-WE is able to utilize non-precious metal catalysts, such as nickel-based catalysts, thus showing clear advantages in terms of cost and resource accessibility. This technology reduces dependence on scarce resources while providing a more economical and sustainable energy conversion solution

Current PEM-WE technology relies on fluoropolymers as its core component. However, during the production of tetrafluoroethylene, fluorocarbon gases are emitted, which has a significant negative impact on the environment. In light of this, the European Commission is actively pushing for restrictions on the future use of these fluorinated materials. It is expected that a comprehensive fluoride ban will be implemented by 2027, which will undoubtedly pose a challenge to PEM-WE technology that relies on fluoride membranes. Its future development direction and feasibility remain an issue that needs attention. In comparison, AEM-WE technology has greater flexibility in the selection of membrane materials. AEM can choose to use less toxic production process routes, thus avoiding potential risks associated with environmental impacts in the long term. In addition, AEM membranes have lower costs compared to PEM membranes, which further enhances their competitiveness in the market.

PEM-WE technology has certain limitations in terms of operating conditions. It requires ultrapure water and exhibits a high sensitivity to impurities in the water supply, such as ions of metallic elements such as iron, copper, chromium and sodium. This may result in the need for additional investment in water purification systems to meet their water quality requirements. In contrast, alkaline electrolysis (AEM) technology significantly reduces the degree of water purification required. In addition, AEM electrolysis also reduces the reliance on complex gas management and cooling systems, which not only simplifies the operating process but also effectively reduces the economic cost of the entire system.

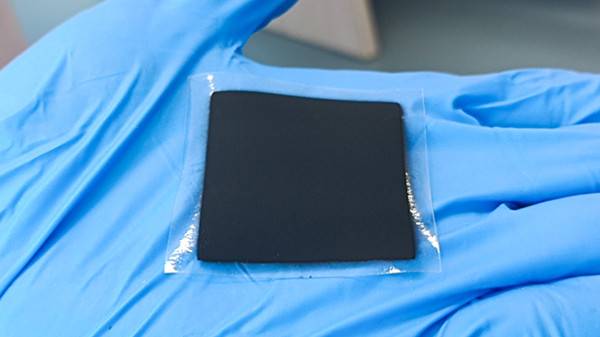

Hydrogen production by electrolysis of water is the most advantageous method for producing hydrogen. Utrasonic coating systems are ideal for spraying carbon-based catalyst inks onto electrolyte membranes used for hydrogen generation. This technology can improve the stability and conversion efficiency of the diaphragm in the electrolytic water hydrogen production device. Cheersonic has extensive expertise coating proton exchange membrane electrolyzers, creating uniform, effective coatings possible for electrolysis applications.

Cheersonic ultrasonic coating systems are used in a number of electrolysis coating applications. The high uniformity of catalyst layers and even dispersion of suspended particles results in very high efficiency electrolyzer coatings, either single or double sided.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions