Analysis of Guidewire Coating

1. Overview of Guidewire

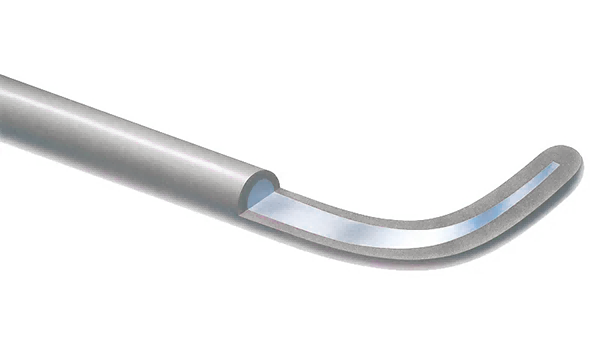

- Definition and Use: Guidewire is an interventional medical device, mainly used to guide other medical devices (such as catheters, stents, etc.) to specific parts in human duct systems such as blood vessels, bile ducts, and ureters. It plays a “navigation” role, helping doctors to perform various interventional treatment operations more accurately and safely, such as guiding balloon catheters and stents to coronary artery stenosis in percutaneous coronary intervention (PCI).

- Structural Features: Guidewires are generally composed of core wires, winding wires, and coatings. The core wire is the main structure of the guidewire, providing the basic strength and shape retention of the guidewire; the winding wire is usually wrapped around the outer layer of the core wire to enhance the flexibility and torque transmission performance of the guidewire; the coating covers the surface of the guidewire to improve the interaction between the guidewire and the human tissue and blood vessel wall, reduce friction, and improve the operability and safety of the guidewire.

2. The purpose and importance of guidewire spraying

- Improving lubricity: Spraying a special coating can significantly reduce the friction of the guidewire in blood vessels or other pipes. This allows the guidewire to pass through narrow and curved areas more smoothly and reduce damage to the blood vessel wall. For example, in neurovascular intervention, a guidewire sprayed with an ultra-slip coating can more easily pass through thin and tortuous cerebral blood vessels.

- Enhanced biocompatibility: The guidewire is in direct contact with human tissue, and a good biocompatible coating can reduce the body’s immune response and inflammatory response to the guidewire. By spraying biocompatible materials such as heparin, hydrophilic polymers, etc., the guidewire can better adapt to the internal environment of the human body and reduce the risk of complications such as thrombosis.

- Improved visibility: Some guidewires will be sprayed with materials with development functions to enhance visibility in imaging examinations (such as X-rays, CT, etc.). In this way, doctors can more accurately judge the position and direction of the guidewire, which helps to accurately perform interventional operations.

3. Spray material type

- Hydrophilic polymer coating material:

Polyethylene glycol (PEG): PEG is a commonly used hydrophilic polymer with good water solubility and biocompatibility. When sprayed on the surface of the guidewire, the PEG coating can absorb water and form a hydration layer on the surface of the guidewire, thereby effectively reducing friction and making the guidewire slide more smoothly in the blood vessel.

Hyaluronic acid (HA): It is a polysaccharide naturally present in human tissues with excellent lubricity and biocompatibility. Spraying hyaluronic acid on the guidewire can simulate the body’s own lubricating environment, reduce friction between the guidewire and the blood vessel wall, and reduce damage to vascular endothelial cells. - Antithrombotic materials:

Heparin: Heparin is a widely used anticoagulant. Spraying it on the surface of the guidewire can effectively prevent blood from coagulating and forming thrombi on the surface of the guidewire. The heparin coating inhibits the activity of coagulation factors by binding to antithrombin III in the blood, thereby reducing the risk of thrombosis.

Heparin-like materials: Some synthetic materials with heparin-like structures and functions are also used for guidewire spraying. These materials can provide continuous antithrombotic functions and may have advantages over heparin in some aspects, such as better stability and operability. - Development materials:

Barium salts and iodine compounds: Spraying barium salts (such as barium sulfate) or iodine compounds on the surface of the guidewire can make it develop under X-rays. These materials can absorb X-rays, making the guidewire clearly visible in the image. The doctor can observe the position and movement of the guidewire in real time based on the image and accurately guide the interventional operation.

4. Spraying method

Ultrasonic spraying is particularly suitable for coating guidewires. The coating method includes coating a non-hydrophilic polymer on the surface of the medical device guidewire and coating a hydrophilic polymer on the non-hydrophilic polymer layer. The non-hydrophilic polymer is applied in the form of a composition comprising a non-hydrophilic polymer and water, preferably an aqueous dispersion.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions