Ultrasonic Spray for Photoresist and Polyimide Coatings

Ultrasonic spray for photoresist and polyimide coatings is indeed a highly effective and versatile process that offers numerous advantages over traditional coating methods. This technique leverages the power of ultrasonic energy to atomize the coating material into a fine mist, which is then sprayed onto the substrate in a controlled and precise manner.

Key Advantages of Ultrasonic Spray for Photoresist and Polyimide Coatings

- Fine Control of Coating Parameters: Ultrasonic coating systems provide exceptional control over key parameters such as flow rate, coating speed, and deposition amount. This enables manufacturers to achieve precise coatings with tight tolerances, which is crucial for high-precision applications like semiconductor manufacturing and microelectronics.

- Low Velocity Spray Shaping: The low velocity of the ultrasonic spray enables precise shaping of the atomized spray pattern. This allows for targeted coating of specific areas, minimizing overspray and ensuring that only the desired regions are coated. Additionally, the low velocity spray helps to reduce the risk of damage to delicate substrates.

- Uniform, Thin Layers: The ultrasonic spray process produces very thin, uniform layers of photoresist and polyimide. This is critical for ensuring consistent performance and reliability in the final product. The uniform coating also facilitates the removal of the photoresist or polyimide during subsequent processing steps.

- Repeatability: The ultrasonic spray process is highly repeatable, allowing manufacturers to consistently achieve the same coating results across multiple substrates. This is essential for ensuring quality control and maintaining consistency in large-scale production runs.

- Simple, Economical, and Scalable: Ultrasonic coating systems are relatively simple to operate and maintain, making them an economical choice for many manufacturers. Additionally, these systems can be scaled up or down to meet the needs of different production volumes, making them suitable for both small-scale R&D and large-scale manufacturing.

Applications

Ultrasonic spray for photoresist and polyimide coatings is widely used in industries such as:

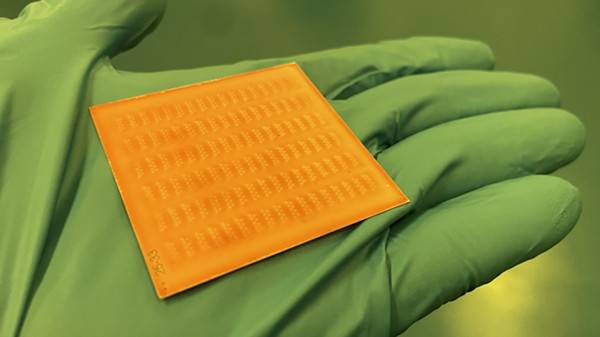

- Semiconductor Manufacturing: For the deposition of photoresist layers during the lithography process, which is a critical step in the fabrication of integrated circuits.

- Microelectronics: For the coating of sensors, actuators, and other microdevices with polyimide films for electrical insulation, protection, or other functional purposes.

- Flexible Electronics: For the production of flexible displays, sensors, and other devices that require conformal coatings of photoresist or polyimide.

In conclusion, ultrasonic spray is a highly effective and versatile process for photoresist and polyimide coatings. Its ability to provide fine control over coating parameters, produce uniform, thin layers, and ensure repeatability makes it an attractive choice for manufacturers in a variety of industries.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions